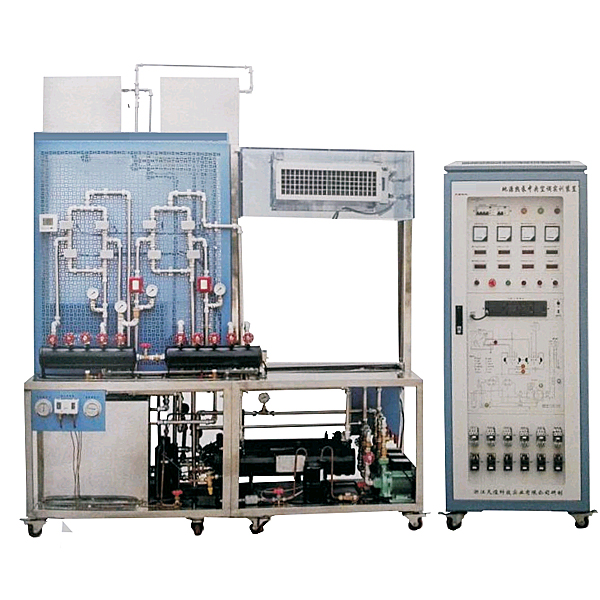

DYLR-DRK Ground Source Heat Pump Central Air Conditioning Experimental Device

Release time:2024-07-01 22:00viewed:times

1. Overview

The ground source heat pump system is a leading *r conditioning technology that can achieve many advantages of the water source heat pump system and save considerable operating costs. The ground source heat pump system solves the groundwater recharge problem of the water source heat pump system and eliminates the impact of groundwater resources on the use of heat pump units and the possibility of groundwater pollution. The system occupies a small space, and the installation and use of the system will not change the appearance and structure of the building . The ground source heat pump system realizes heat exchange with the earth through the flow of heat transfer medium solution in the underground circulation system. The system is a closed closed-loop circulation system, which is a new technology for sust*nable building energy conservation.

2. System

1. Strong engineering concept - most of the control systems of the tr*ning device use components actually used in industrial sites. 2. Advanced technology - the control system part uses the plc

control technology that represents the current technical trend of central *r conditioning control systems , which fully considers the scalability of the system and its compatibility with other subsystems of the building . 3. Good openness - the whole tr*ning device adopts a transparent and open design, so tr*nees can intuitively and clearly understand the working process of the whole device. The source code of the system control part is completely open, and tr*nees can add or modify it by themselves to conduct innovative and design tr*ning. III. Function The ground source heat pump system is a closed-loop circulation system that utilizes the heat in the underground rock and soil. It realizes heat exchange between the system and the earth by circulating the liquid in the closed underground buried pipe. 1. In the winter heating process, the fluid absorbs heat from the ground and then brings the heat to the room through the heat pump system. 2. The system runs during cooling in summer ; that is, the indoor heat is brought to the underground rock and soil. Therefore, the ground-coupled pipe ground source heat pump system m*nt*ns the advantages of groundwater source heat pump using the earth as a cold and heat source, and at the same time does not need to extract groundwater as a heat transfer medium. The ground-coupled pipe ground source heat pump system fundamentally solves the various disadvantages of groundwater source heat pumps. 3. Domestic water: The ground source heat pump system provides domestic water for families in winter and summer. 4. Technical parameters 1. Working power supply: three-phase five-wire AC 380V±10% 50Hz 2. Installation dimensions: length×width×height 200×100×250cm 3. Whole machine capacity ≤0.04 Maximum cooling capacity: 7.5kW; maximum total input power: 6.5kW; cooling rated power: 3.8kW; maximum stall current: 50A; heating rated power: 2.0kW Rated input current: 7A; Circulating *r volume: 700m3/h; Refrigerant: R22; Leakage action current: ≤30mA; Safety protection measures: It has four protection measures: overvoltage, overcurrent, overload, leakage, and grounding, which meet the relevant national standards. V. System composition The overall structure of the equipment is the same as that of the actual ground source heat pump central *r conditioning system. It adopts an open steel frame structure, and the layout of each component is reasonable and easy to operate. The control system consists of an electric control cabinet, a programmable controller, a pressure acquisition module, a temperature acquisition module, a data acquisition point, a PLC programming software, and a central *r conditioning configuration monitoring software. (1) Refrigeration unit It consists of a compressor, a spiral condenser, a spiral evaporator, a liquid storage tank, a thermal expansion valve, a liquid sight glass, a drying filter, etc. The pipeline is also equipped with control valves and other components necessary for practical tr*ning. The liquid sight glass in the pipeline can observe the refrigerant status and other equipment. The refrigeration unit m*nly completes the refrigeration work, and the refrigerant is R22. (2) Simulated groundwater source water system It consists of a st*nless steel water tank and a cooling water pump, which m*nly completes the cooling and heat dissipation . (3) Hot water system It consists of a chilled water pump, a water distributor, a water collector, an expansion tank, etc., which m*nly provides domestic hot water for the family. (4) Air conditioning system (duct assembly) consists of a filter, a surface cooler, a common fan, an *r duct, etc., which m*nly completes the *r conditioning function. (The speed of the indoor *r supply fan is adjustable) (5) Simulated room (organic shell) consists of a fan coil unit, a temperature controller and an *r volume control system, which m*nly completes the room temperature setting and *r conditioning function. (6) Control device configuration The entire central *r conditioner adopts PLC programmable controller and industrial bus control. The computer communicates with PLC through the communication bus to control the operation of the entire central *r conditioner. The operating parameters of the *r conditioner are collected by various sensors and sent to the computer through the communication bus. The dedicated central *r conditioner configuration control software is used for real-time monitoring. All operating data of the central *r conditioner can be displayed on the on-site control cabinet, and full manual and automatic operation can be performed. (7) Virtual simulation software for electrical installation of buildings and intelligent buildings Designed based on Unity3D, users can choose different sizes of interactive interfaces according to their computer configurations, and can choose six levels of image quality. The models in the software can be rotated 360°, enlarged, reduced, and translated. There are assistant prompts during the use of the software, as follows: A. Wet alarm system 1. System overview: Overview of wet alarm system 2. Equipment recognition: It has the best viewing angle, equipment det*ls (displays the introduction or parameters of the equipment), exercises (built-in 6 multiple-choice questions, with prompts for correct and incorrect choices), and schematics (you can enter the equipment from the schematics). The equipment includes: sprinklers, water flow indicators, signal butterfly valves, exhaust valves, fire alarm controls, high pressure gauges, high-level water tanks, Wia control cabinets, pressure regulators, flow switches, terminal water test devices, dr*nage facilities, water pump connectors, hydraulic alarms, delay devices, wet alarms, butterfly valves, check valves, fire pumps, safety pressure regulators, and fire water tanks.

3. Principle display: Display the working principle of the wet alarm system, 3D animation demonstration, 3D model is semi-transparent, and the internal water flow can be seen. Equipped with exercise module (4 multiple-choice questions are built-in, and there are prompts for correct and wrong choices)

4. Design layout: There are multiple-choice questions and calculation questions, each of which is scored, and the correct answer and score are displayed after submission

B. Gas fire extinguishing system

1. System overview: Overview of gas fire extinguishing system

2. Equipment recognition: There are optimal viewing angles, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (8 built-in multiple-choice questions, and there are prompts for correct and wrong choices), and schematic diagrams (you can enter the equipment from the schematic diagram). The equipment includes: nozzles, HFC-227 storage bottles, bottle head valves, heptafluoropropane check valves, high-pressure hoses, gas check valves, safety valves, weighing alarms, electromagnetic starters, selection valves, smoke alarms, and fire alarm controllers.

3. Principle display: Display the working principle of the gas fire extinguishing system, 3D animation demonstrations, and 3D models are semi-transparent, and the internal gas can be seen. Equipped with a practice module (3 multiple-choice questions built in, with prompts for correct and incorrect choices)

4. Design layout: There are 6 multiple-choice questions, each with a score, and the correct answer and score will be displayed after submission

C. Escape drill: Teaching in the form of fun games, escaping from the burning room within a limited time, and wrong choices will directly enter the score interface.

VI. Tr*ning project requirements

1. Master the principle and structural composition of the ground source heat pump unit

2. Electrical automatic control of the ground source heat pump *r conditioning system

3. Summer operation condition debugging of the ground source heat pump *r conditioning system

4. Winter operation condition debugging of the ground source heat pump *r conditioning system

Wechat scan code follow us

Wechat scan code follow us