|

ZR-119 type Ordinary rapid filter device |

M*n parameters and configuration: Processed water volume: 1.7~2.2 m3/h, the filter tank is divided into 3 grids, device dimensions: 1300×700×1300 mm, power supply 220V, power 500W configuration: 1 set of plexiglass fast filter tank, 1 water tank, 1 flow meter, 1 water pump, 1 set of each of three types of quartz sand filter materials, connecting pipes and ball valves, 1 electric control box, leakage protection switch, push button switch, 1 set of st*nless steel stand with movable wheels, etc. |

|

ZR-120 type Siphon type mobile hood filter device |

M*n parameters and configuration: Processed water volume: 1.5~2.5 m3/h, device dimensions 1400 mm×800 mm×1700 mm, power supply 220V power 900W configuration: The device consists of 1 set of filter tank, 1 set of mobile vehicle, 1 motor, 1 speed regulator, 1 water tank, 1 flow meter, 1 water pump, connecting pipes and ball valves, 1 electric control box, leakage protection switch, push button switch, 1 set of st*nless steel stand with mobile wheels, etc. |

|

ZR-125 type Valveless filter device |

M*n parameters and configuration: Processed water volume: 1~1.5m3/h, device dimensions: 1000mm×600mm×2100mm, power supply 220V, power 200W, configuration: all components of plexiglass valveless filter, water distribution system, flushing water tank, 1 water pump, 1 electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel bracket with movable wheels, etc. |

|

ZR-126 type Siphon filter device |

M*n parameters and configuration: Filtered water volume: 0.7-1.2m3/h, device dimensions: 800m×470m×1600mm, power supply 220V, power 200W, configuration: all components of siphon filter, vacuum system, flushing siphon, flushing dr*n, etc. Water distribution tank, 1 liquid flow meter, 1 water pump, 1 vacuum pump, connecting pipes and ball valves, 1 electric control box, leakage protection switch, push button switch, 1 set of st*nless steel stand with moving wheels, etc. |

|

ZR-127 type Dual valve filter device |

M*n parameters and configuration: Filtered water volume: 1.2~1.6m3/h, device dimensions: length 805mm width 470mm height 800mm, power supply 220V, power 200W Configuration: All components of the plexiglass double-valve filter, water distribution tank, 1 liquid flow meter, 1 water pump, 1 vacuum pump, connecting pipes and ball valves, 1 electric control box, leakage protection switch, push button switch, 1 set of st*nless steel stand with movable wheels, etc. |

|

ZR-128 type Rectangular single-cell V-shaped filter device |

M*n parameters and configuration: Processing and filtering water volume: 1m3/h, device dimensions: 1600mm×500mm×1500mm, power supply 220V power 800W configuration: 1 set of single-cell V-shaped filter tank with organic glass body, 1 water distribution tank, 2 water pumps, 1 rotor flowmeter, 1 gas flowmeter, 1 clean water tank, 1 *r compressor, 9 large filter caps, connecting pipes and ball valves, 1 electric control box, leakage protection switch, push button switch, st*nless steel stand with movable wheels, etc. |

|

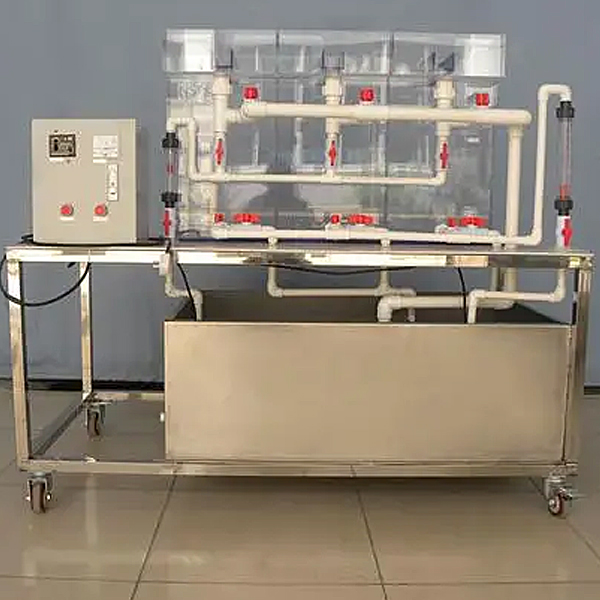

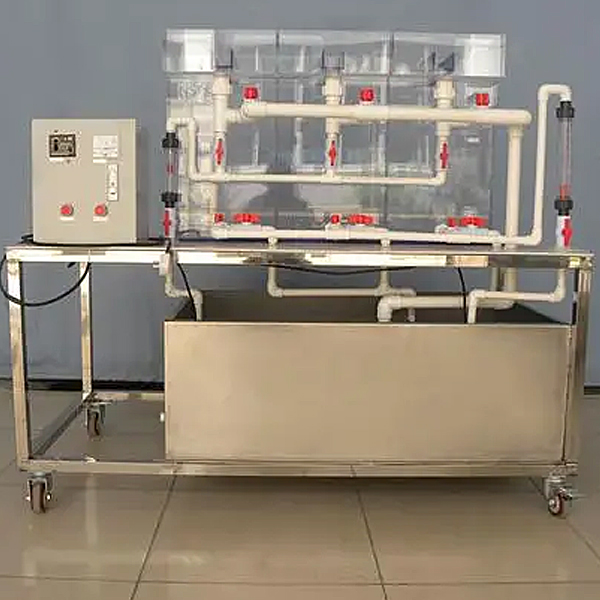

ZR-152 "Multi-layer filter media" rapid filter |

M*n parameters and configuration: Processed water volume: 0.3~5m3/h, device dimensions: 1000×500×1400 mm, voltage 220V power 500W configuration: 1 PVC water distribution tank, 1 set of multi-layer filter media filter, 1 PVC water outlet tank, 1 st*nless steel water pump; 1 backwash fan, 1 rotor flowmeter, 1 gas flowmeter, 1 batch of ceramsite, 1 batch of quartz sand, 1 batch of polyhedral hollow balls, 1 batch of activated carbon, 1 electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel stand with movable wheels, etc. |

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap