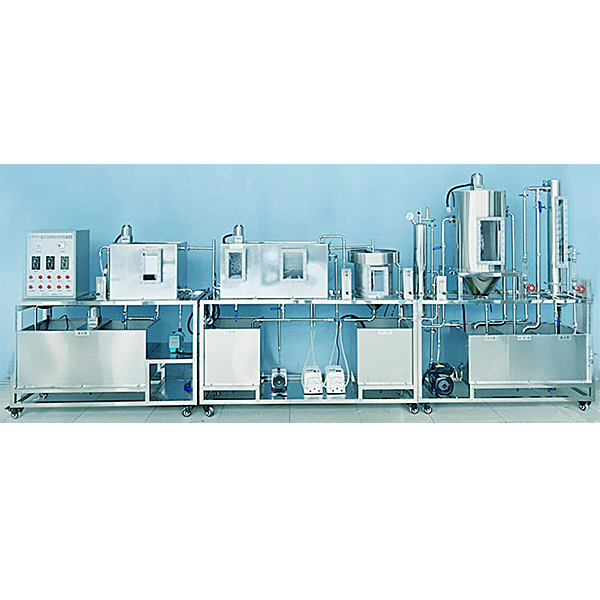

DY-337 Domestic Sewage Treatment Water Reuse Training Platform

Release time:2024-06-29 23:30viewed:times

1. Experimental purpose

1. Understand the commonly used unit operation technologies for centralized water reuse in domestic sewage treatment

2. Master the treatment process composed of these unit operations

3. Observe the behavior of wastewater, suspended solids and *r in the treatment process

4. Determine its design parameters and analysis of treatment results through actual treatment experiments on domestic sewage.

2. M*n technical indicators and parameters:

1. Treatment water volume: 30~50L/h;

2. Dissolved gas pressure 0.2~0.5Mpa;

3. Working power supply 220V, safety protection: with grounding protection, leakage protection, overcurrent protection, power 950W

4. Electrical line installation requirements: Arrange wire troughs, standardize the wire materials such as power lines and control lines, and have insulation and arc protection characteristics;

5. Device dimensions: 2000mm×500mm×1500mm.

6. Working power supply: AC220V±10%, 50Hz, single-phase three-wire system, power 1100W, safety protection: with grounding protection, leakage protection, overcurrent protection,

2. M*n parameters and configuration:

1. 1 raw water tank: white PP board material, thickness 10mm, 400×350×500mm, a dr*n valve is installed on the bottom plate to dr*n the water;

2. 1 clean water tank: white PP board material, thickness 10mm, 300×350×500mm, a dr*n valve is installed on the bottom plate to dr*n the water;

3. Equipped with 1 raw water tank stirring motor and 1 set of 304 st*nless steel stirring paddle; (power 15W, speed 120rpm), (including 1 speed regulator)

4. 1 set of coagulation dosing box, (including accessories stirring motor, speed regulator, dosing flow meter, dosing pump, dosing box), transparent plexiglass material, wall thickness 8mm, Ø300mm×400mm,

5. Vertical flow flotation tank: including accessories: 1 set of copper dissolved *r releaser, transparent plexiglass material, wall thickness 8mm, Ø400mm×650mm.

6. 1 set of motor scraping system device (power 25W, speed 150rpm), 1 set of 304 st*nless steel stirring paddle.

7. 1 high-pressure water pump (rated flow 0.1m3/h, head 15m, power 900W),

8. 1 set of 304 st*nless steel pressure dissolved gas tank, wall thickness 3mm, Ø100mm×800mm, including 1 pressure gauge, working pressure 0.3-0.5Mpa (adjustable), volume 13L;

9. 1 set of secondary sedimentation tank, transparent organic glass material, wall thickness 8mm, Ø250mm×300mm,

10. 1 set of quartz sand filter tank (including quartz sand filler) transparent organic glass material, wall thickness 10mm, 300×250×400mm,

11. 1 anti-corrosion water inlet pump (rated flow 0.6m3/h, head 5m, power 20W),

12. 1 *r compressor (power supply 220V, power 550W, exhaust volume 36L/min, pressure 0.4-0.8MPa; gas volume 30L),

13. 1 rotor flowmeter (range 10-100L/H),

14. 1 gas flow (range 30~300L/h).

15. 1 water flowmeter for dissolved gas tank (range 60~600L/h).

16. Experimental table (10mm thick PP white board),

17. Power control system: 1 double-sided matte dense spray plastic electric control box, leakage protector (Delixi brand), voltmeter, lockable button switch, wire pipe, etc.

18. Matching PPR connecting pipes and valves.

19. St*nless steel frame experimental table (30mm×30mm st*nless steel square tube, equipped with casters for universal wheels with locking feet), etc.

20. Virtual simulation software for electrical installation of building and intelligent building Based on unity3d design, users can choose different sizes of interactive interface according to computer configuration, and can choose six levels of image quality. The model in the software can be rotated 360°, enlarged, reduced, and translated. There are assistant prompts during the use of the software, the contents are as follows: A. Wet alarm system 1. System overview: Overview of wet alarm system 2. Equipment recognition: It is equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (built-in 6 multiple-choice questions, with prompts for correct and wrong choices), and schematic diagrams (you can enter the equipment from the schematic diagram). The equipment includes: sprinklers, water flow indicators, signal butterfly valves, exhaust valves, fire alarm controls, high-pressure gauges, high-level water tanks, Wia control cabinets, pressure-stabilizing tanks, flow switches, terminal water testing devices, dr*nage facilities, water pump connectors, hydraulic alarms, time delays, wet alarms, butterfly valves, check valves, fire pumps, safety pressure-stabilizing valves, and fire water tanks. 3. Principle display: Display the working principle of the wet alarm system, 3D animation demonstration, and semi-transparent 3D models , so that the internal water flow can be seen. Equipped with practice module (built-in 4 multiple-choice questions, with prompts for correct and incorrect choices) 4. Design layout: There are multiple-choice questions and calculation questions, each with scores, and the correct answer and score will be displayed after submission B. Gas fire extinguishing system 1. System overview: Overview of gas fire extinguishing system

2. Equipment recognition: It has the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (8 built-in multiple-choice questions, with prompts for correct and wrong choices), and schematics (you can enter the equipment from the schematics). The equipment includes: nozzles, HFC-227 storage bottles, bottle head valves, heptafluoropropane check valves, high-pressure hoses, gas check valves, safety valves, weighing alarms, electromagnetic starters, selector valves, smoke alarms, and fire alarm controllers.

3. Principle display: It shows the working principle of the gas fire extinguishing system, with a three-dimensional animation demonstration and a semi-transparent three-dimensional model, so that the internal gas can be seen. It is equipped with an exercise module (3 built-in multiple-choice questions, with prompts for correct and wrong choices)

4. Design layout: There are 6 multiple-choice questions, each of which is scored. After submission, the correct answer and score will be displayed.

C. Escape drill: Teaching is carried out in the form of fun games. Escape from the burning room within a limited time. If you make a wrong choice, you will directly enter the score interface.

Wechat scan code follow us

Wechat scan code follow us