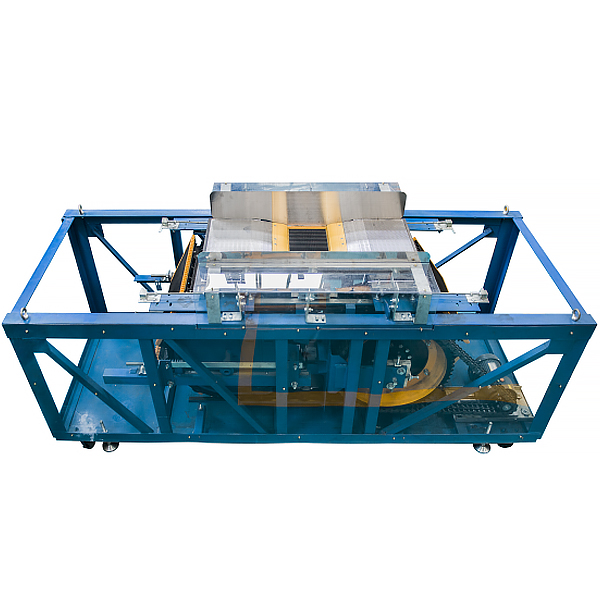

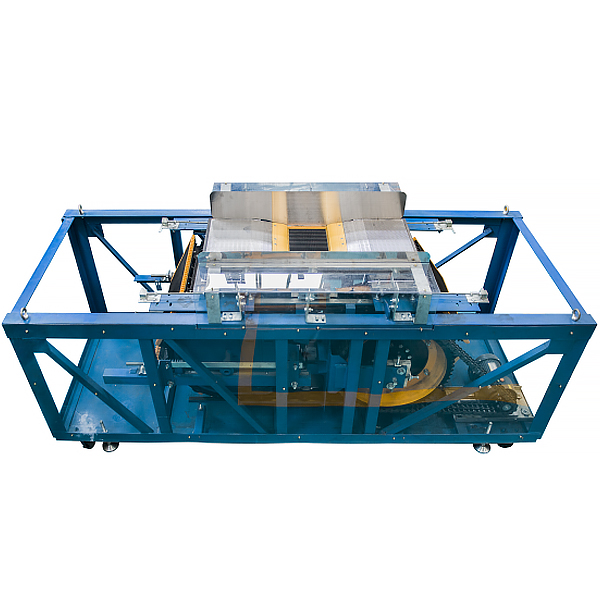

| Serial number | name | M*n Specifications | quantity | unit | Remark |

| 1 | Steel structure frame | Material: Q235 standard steel; surface spray-p*nted | 1 | set | |

| 2 | Reducer | Motor power: 750W; reducer reduction ratio: 150:1; working voltage: AC220V/380V; rated current: 3.5A/2.0A; rated speed: 1400/1700 r/min; | 1 | set | There are two wiring methods for reducer: AC220V/380V. |

| 3 | Drive ch*n | Pitch: 31.75mm; | 2 | strip | |

| 4 | step | Material: st*nless steel; roller diameter: ∅70mm; rim width: 25mm; rim material: polyurethane; roller bearing model: 6240-2RS; | 1 | set | |

| 5 | Step transmission ch*n | Pitch: 133.33mm; Step distance: 400mm; Roller diameter: ∅70mm; Rim width: 25mm; Rim material: polyurethane; Roller bearing model: 6240-2RS; | 2 | strip | |

| 6 | Tensioning device | Number of teeth of step sprocket: 16; Unit pitch circle diameter: 5.1258; | 1 | set | Including step sprocket, shaft, tensioning trolley and step ch*n spring, etc.; |

| 7 | Control cabinet | Customized | 1 | set | Contactor: Schneider; |

| 8 | Mobile m*ntenance switch | 1 | indivual | ||

| 9 | Mobile running lights | DC220V | 1 | indivual | |

| 10 | Tr*ning tools | 1 | set | See the supporting tools list for det*ls | |

| 11 | material | Related Instructions | 1 | set |

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap