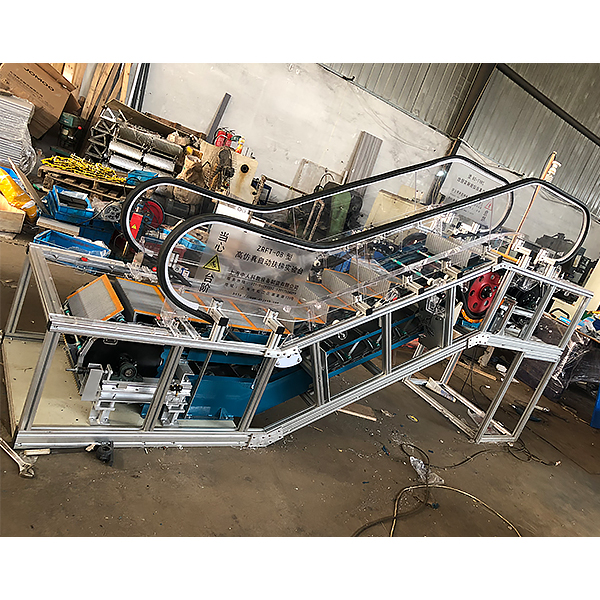

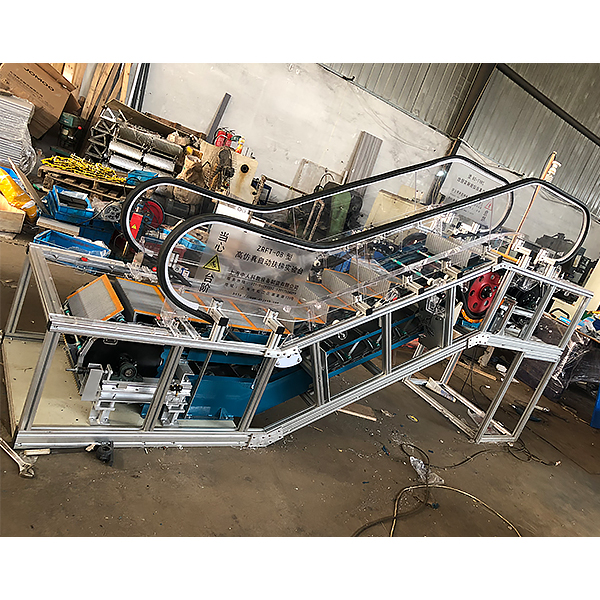

DYFT-2019 aluminum alloy escalator experimental platform

Release time:2024-06-26 22:00viewed:times

The detachable simulation escalator model is composed of aluminum alloy profile frame, traction device, worm gear drive device, handr*l drive device, aluminum alloy guide r*l of ladder path, step transmission ch*n, aluminum alloy step, comb front plate, electrical control system and other parts. The bearing support seat of the m*n rotating parts is made of iron. The electrical control adopts Mitsubishi PLC system.

I. Technical parameters

1. Input power: three-phase four-wire (or three-phase five-wire) AC220V±10%, power frequency 50Hz;

2. Working environment: ambient temperature is -5℃~+40℃, relative humidity is <85% (25℃);

3. Machine capacity: ≤2.5kVA;

4. Overall size: 4350mm (length) × 1200mm (width) × 2520mm (height);

laboratory table body: 4350mm×1200mm×820mm

console: 1200×750×1210mm (length*width*height);

5. Lifting height: 600mm;

6. Step running speed 0.5m/s;

7. Load capacity: 200KG;

8. Mode: PLC programmable control, variable frequency section start/operation;

9. Monitoring system: real-time monitoring of voltage and current conditions;

10. Protection: It has protective grounding, overload, overcurrent, and leakage current protection functions, and its safety complies with national standards.

11. Safety devices: traction ch*n break protection device, comb tooth foreign body protection device, handr*l entrance safety protection device, step sinking protection device, drive ch*n break protection device, handr*l break protection device, brake, mechanical locking device, etc.

2. M*n components

1. Driving device: The driving device is m*nly composed of driving sprocket, step sprocket, handr*l driving sprocket, m*n shaft and brake wheel or ratchet. The device obt*ns power from the driving machine and drives the steps and handr*ls through the driving ch*n to realize the m*n movement of the escalator. It can also brake in an emergency to prevent passengers from slipping backwards and ensure the safety of passengers. The device is assembled in the upper platform (upper truss).

2. Tensioning device: The tensioning device is composed of ladder sprocket, shaft, tensioning trolley and spring for tensioning the step ch*n. The tension of the tensioning spring can be adjusted by a nut to keep the step ch*n in good working condition when the escalator is running. When the step ch*n breaks or stretches, the roller on the tensioning trolley is precisely guided to move, so that its safety device (step ch*n break protection device) works and the escalator stops running immediately.

3. Guide r*ls: The step running and return guide r*ls are made of aluminum alloy, which has the characteristics of light weight, high relative rigidity, high manufacturing precision, etc., and is easy to assemble and adjust.

4. Step ch*n: The step ch*n is supported by a support wheel with permanent lubrication, and the step wheel on the step ch*n can run smoothly on the sprocket of the guide r*l system, drive device and tensioning device; it also makes the load evenly distributed and prevents premature wear of the guide r*l system, especially in the reverse area where the two step ch*ns are connected by the step shaft, ensuring the stability of the overall operation of the step ch*n.

5. Steps: Made of aluminum alloy.

6. Handr*l drive device: It is directly driven by the drive device through the handr*l drive ch*n, without the need for an intermediate shaft. The handr*l belt drive wheel rim has an oil-resistant rubber friction layer to ensure that the handr*l belt and the step run synchronously.

Wechat scan code follow us

Wechat scan code follow us