|

ZR-109 type Mechanical reaction inclined plate inclined tube sedimentation tank |

M*n parameters and configuration: Processed water volume: 0.5m3/h, device dimensions: 1100mm×550mm×1500mm, power supply 220V power 370W, configuration: the m*n body is composed of a mechanical reaction tank and an inclined plate and inclined tube sedimentation tank, 1 water distribution tank, 1 water pump, 1 flow meter, 1 electric control box, 1 set of leakage protection switches, 2 push button switches, connecting pipes and ball valves, a st*nless steel stand with movable wheels, etc. |

|

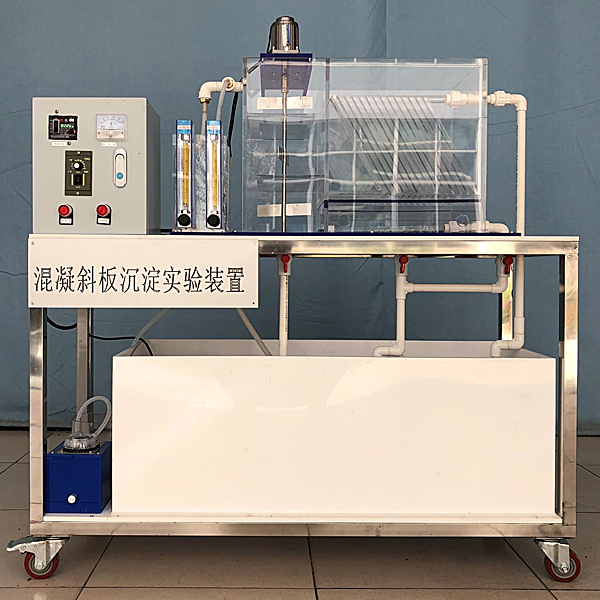

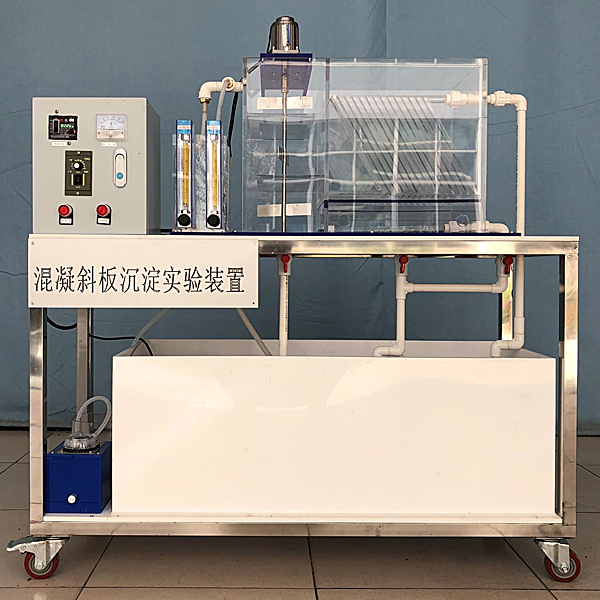

ZR-110 type Mechanical reaction co-current inclined plate sedimentation tank |

M*n parameters and configuration: water treatment capacity (adjustable): 0.5m3/h, device dimensions: 1000mm×550mm×1500mm, power supply 220V, power 370W, configuration: the m*n body is composed of a reaction tank and an inclined plate, and all the devices in the tank. 1 water distribution tank, water pump, 1 flow meter, metal electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel stand with movable wheels, etc. |

|

ZR-111 type Co-current inclined plate sedimentation tank device |

M*n parameters and configuration: water treatment capacity (adjustable): 0.6m3/h, device dimensions: 900mm×500mm×1500mm, power supply 220V, power 200W, configuration: the m*n body consists of an inclined plate sedimentation tank, and all the devices in the tank. 1 water distribution tank, water pump, 1 flow meter, electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel stand with movable wheels, etc. |

|

ZR-116 type Horizontal flow sedimentation tank (mechanical scraper) |

M*n parameters and configuration: Processed water volume: 0.3 m/h, device dimensions: 1000mm×400mm×1300mm, power supply 220V power 300W, configuration: all components of the horizontal flow sedimentation tank, 1 water distribution tank, 1 water pump, 1 liquid flow meter, 1 metal electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel bracket with movable wheels, etc. |

|

ZR-117 type Bidirectional flow inclined plate sedimentation tank device |

M*n parameters and configuration: Processed water volume (adjustable): 0.8m3/h, overall dimensions: 900mm×500mm×1500mm, power supply 220V power 300W Configuration: The m*n body consists of a two-way flow inclined plate sedimentation tank, 1 water distribution tank, a water pump, 1 flow meter, an electric control box, a leakage protection switch, a push button switch, connecting pipes and ball valves, a st*nless steel stand with movable wheels, etc. |

|

ZR-118 type Static sedimentation column equipment (mechanical reaction) |

M*n parameters and configuration: Device dimensions: 600 mm×500 mm×2300 mm, quantity: 1 set (root), power supply 220V power 370W, configuration: 1 set of plexiglass sedimentation column Ø150mm×2000mm, 1 set of st*nless steel agitator in the column, 1 PVC water tank, 1 water pump, 5 copper ball valve sampling ports, 1 electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel bracket with movable wheels, etc. |

|

ZR-123 type Multi-bucket horizontal flow sedimentation tank device |

M*n parameters and configuration: Processed water volume: 0.3 m/h, device dimensions: 1200mm×400mm×1300mm, power supply 220V power 370W, configuration: all components of a multi-bucket horizontal flow sedimentation tank, 1 water distribution tank, 1 water pump, 1 liquid flow meter, 1 electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel bracket with movable wheels, etc. |

|

ZR-302 type Bell type grit chamber |

M*n parameters and configuration: processing flow rate 12 L/s, device dimensions: 1000mm×550mm×1500mm, power supply 220V, power 600W, configuration: the device consists of 1 set of bell-type sand settling tank, 1 water distribution tank, 1 water pump, 1 *r compressor, 1 liquid flow meter, 1 gas flow meter, 1 electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel stand with movable wheels, etc. |

|

ZR-316 type Rectangular combined aeration sedimentation tank |

M*n parameters and configuration: water treatment capacity: 32L/h, mechanical stirring speed: 40-50 rpm, device dimensions: 900mm×450mm×1500mm, power supply 220V, power 300W, configuration: 1 set of aeration sedimentation tank made of organic glass plate, 1 water pump, 1 motor, 1 speed regulator, 1 flow meter, 1 aeration impeller, 1 water distribution tank, 1 electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel stand with movable wheels, etc. |

|

ZR-338 type Radial flow primary sedimentation tank |

M*n parameters and configuration: Processed water volume: 0.36~0.56m3/h, Sedimentation time: 1.5~2h, Sedimentation tank size: φ400mm×550mm, Device overall dimensions: 700mm×500mm×1300mm, Power supply 220V, Power 300W, Configuration: The m*n body includes all the components of the radial flow sedimentation tank, equipped with 1 set of honeycomb inclined tubes, 1 set of mechanical scraper, 1 water distribution tank, 1 speed regulating motor, 1 speed governor, 1 rotor flowmeter, 1 water pump, 1 electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel stand with movable wheels, etc. |

|

ZR-346 type Cyclone type grit chamber |

M*n parameters and configuration: water treatment capacity: 20-50L/h, device dimensions: 700mm×500mm×1400mm, power supply 220V power 500W, configuration: 1 set of plexiglass cyclone sand settling tank, 1 water distribution tank, 1 water pump, 1 stirring motor, 1 speed regulator, 1 rotor flowmeter, 1 electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel stand with movable wheels, etc. |

|

ZR-372 type Aerated grit chamber |

M*n parameters and configuration: water treatment volume: 0.16~1.2m3/h, horizontal flow rate is generally: 0.08~0.12m/s, residence time of sand-cont*ning wastewater in the pool: 5~10min, aeration tank size: 800mm×420mm×600mm, device overall dimensions: 1100mm×500mm×1600mm, power supply 220V power 400W, configuration: 1 set of aeration and grit chamber made of plexiglass, equipped with 1 low-noise oxygenation pump, 1 water pump, 1 water distribution tank, 1 flow meter, 1 electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel stand with movable wheels, etc. |

|

ZR-377 type Radial flow sedimentation tank (with scraper) |

M*n parameters and configuration: Processed water volume: 0.36~0.56m3/h, Sedimentation time: 1.5~2h, Sedimentation tank size: φ400mm×550mm, Device overall dimensions: 700mm×500mm×1300mm, Power supply 220V, Power 300W, Configuration: The m*n body includes all the components of the radial flow sedimentation tank, equipped with 1 set of honeycomb inclined tubes, 1 set of mechanical scraper, 1 water distribution tank, 1 speed regulating motor, 1 speed governor, 1 rotor flowmeter, 1 water pump, 1 electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel stand, etc. |

|

ZR-378 type Multi-bucket horizontal flow sedimentation tank |

M*n parameters and configuration: Processed water volume: 0.3 m3/h, Overall dimensions: 1200mm×400mm×1300mm, Power supply 220V Power 370W, Configuration: All components of a multi-bucket horizontal flow sedimentation tank, including 1 water distribution tank, 1 water pump, 1 *r compressor, 1 liquid flow meter, 1 electrical control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel bracket with movable wheels, etc. |

|

ZR-379 type Vertical flow sedimentation tank |

M*n parameters and configuration: Processed water volume: 0.6 m3/h, Overall dimensions: 700mm×400mm×1400mm, Power supply 220V Power 200W, Configuration: All components of a vertical flow sedimentation tank, including 1 water distribution tank, 1 water pump, 1 liquid flow meter, 1 electrical control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel brackets, etc. |

|

ZR-382 type Aerated sedimentation tank |

M*n parameters and configuration: water treatment volume: 2-5L/h. Air volume: 50L/min. Sedimentation tank residence time: 1.5 hours. Dimensions: 1000mm×400mm×1400mm, power supply 220V, power 500W, configuration: aeration sedimentation tank, 1 water distribution tank, 1 water pump, 1 *r compressor, 1 liquid flow meter, 1 gas flow meter, 1 electric control box, leakage protection switch, push button switch, connecting pipes and ball valves, st*nless steel bracket with movable wheels, etc. |

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap