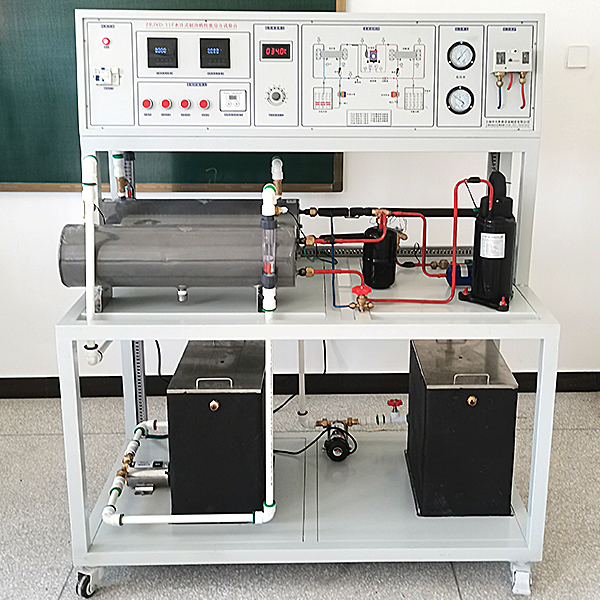

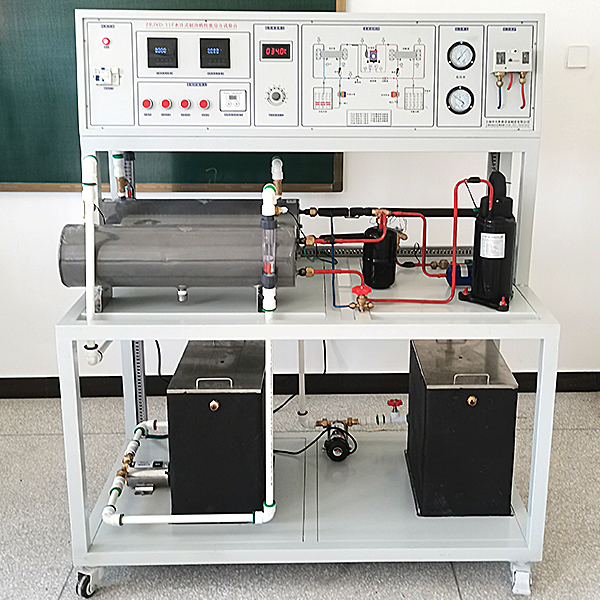

DYJYD-11F water-cooled refrigerator performance comprehensive training device

Release time:2024-06-18 02:30viewed:times

1. Functions of the tr*ning project

1. Use water-cooled units, equipped with fully enclosed refrigeration compressors, condensers, evaporators and other real refrigeration system components, and equipped with intelligent temperature regulators, flow meters, pressure gauges, voltmeters, ammeters and other measuring instruments.

2. Automatic/manual adjustment of refrigerant flow: experimental data can be taken under different evaporation environments. Such as: overheating, overcooling, etc.

3. Familiar with the basic structure and working principle of the vapor compression refrigeration cycle system

4. Understand the performance and use of the international standard GB/T5773-2004 positive displacement refrigeration compressor

5. Use the evaporator liquid refrigerant circulation method (m*n measurement method) to calculate the refrigeration capacity of the refrigeration compressor

6. Use the water-cooled condenser heat balance method (auxiliary measurement method) to calculate the refrigeration capacity of the refrigeration compressor

7. Calculation and analysis of the relative error of the m*n and auxiliary measurement refrigeration capacity

8. Calculation and analysis of the energy efficiency ratio of the refrigeration unit

2. Device features

1. This tr*ning device is in accordance with the international standard GB/T 5773-2004 The tr*ning method of the performance of the positive displacement refrigeration compressor is established, with the "evaporator liquid refrigerant circulation method" as the m*n measurement and the "water-cooled condenser calorimeter method" as the auxiliary measurement

. 2. A 1-horsepower refrigeration unit is used, and both the condenser and the evaporator are plate-type water heat exchangers. The system has a compact structure, a reasonable layout, and a beautiful shape.

3. Refrigeration flow control and quantity control system

1) Under different evaporator pressures, the compressor is tested at different refrigeration capacities, and it has automatic adjustment of compressor overcooling/overheating

2) The mechanical throttling device is difficult to adjust and damaged during the experiment, so that students can learn the method of electronic control, operation adjustment method, and technical parameter adjustment during the experiment.

5) Mode: Touch screen or software connection mode: The compressor exhaust temperature, suction temperature, condensation temperature, and evaporation temperature can be displayed, and the unit subcooling and superheating can be adjusted in real time according to the temperature.

6) Bidirectional flow control module: By automatically adjusting the refrigerant flow to increase the refrigerant flow, the compressor exhaust temperature can be effectively reduced and the compressor's efficient working area can be expanded.

III. Technical performance

1. Input power: single-phase three-wire ~ 220V ± 10% 50Hz

2. Working environment: temperature -10℃ ~ +40℃ relative humidity <85% (25℃) altitude <4000m

3. Device capacity: <2.5kVA

4. Refrigerant: R22

5. Cooling capacity: 1.3kW

6. Weight: 100kg

7. Dimensions: 110cm×70cm×150cm

IV. Basic configuration and functions

1. Control panel: It adopts a double-layer matte dense pattern spray-coated structure with a novel shape. The refrigeration system is arranged on the top layer, which can intuitively display the structure of the refrigeration system; the front is equipped with a power control and measuring instrument function panel. There are four universal wheels with brakes at the bottom for easy movement and fixation.

2. AC control unit: single-phase three-wire 220V AC power supply, the total power supply is controlled by the leakage current protector, and the operating current is 30mA

3. Refrigeration system: 1 fully enclosed compressor, plate condenser, sight glass, dry filter, manual throttle valve, liquid storage device and plate generator

4. Cooling circulating water system: The classroom is connected to tap water.

5. Measuring instruments: 2 power meters (accuracy 0.5 level), respectively measuring heating power and compressor power. The digital display window can measure the active power, reactive power, power factor, voltage, current, frequency and load properties of the load; and can store

6. Data acquisition module display screen

The intelligent system is composed of multiple modules, which can be freely combined through connecting lines according to functional requirements. Module 1: temperature measurement function, module 2: fault setting module function, module 3: temperature, temperature control module: module 4: heating/humidity temperature control

1), temperature/humidity module, communicates with the 5-inch touch screen display through standard communication protocol, and can measure 12 temperatures, 12 temperatures through online name modification.

2) Temperature measurement instrument function: Through the 10K sensor , 12 temperatures can be measured online. They are respectively the compressor suction port temperature, compressor exhaust port temperature, condenser outlet temperature, evaporator inlet temperature, condenser water inlet temperature, condenser water outlet temperature, evaporator water inlet temperature and evaporator water outlet temperature.

3) Humidity measurement instrument function: By changing the humidity sensor, the humidity function in 12 spaces can be measured.

7. Control instrument: 1 high and low pressure controller: Real-time monitoring of the low-pressure side pressure and high-pressure side pressure of the refrigeration system. When the high pressure is higher than the set value or the low pressure is lower than the set value, the controller sends a control signal to cut off the power supply of the compressor.

8. Embedded touch screen host: The system consists of 3 parts: display module, function module, and host software (factory configuration combination based on product performance). Embedded touch screen host, using touch screen control, can directly enter the system adjustment, voltage 5-36V/50HZ, with startup voice function, size 5 inches, memory 156M, capacitive.

9. Single chip microcomputer , PLC programmable design and control virtual simulation software:

This software is developed based on Unity3D, and has built-in experimental steps, experimental instructions, circuit diagrams, component lists, connection lines, power on, circuit diagrams, scene reset, return and other buttons. After the connection and code are correct, the three-dimensional machine tool model can be operated through the start/stop, forward motion, and reverse motion buttons. When the line is connected, the three-dimensional machine tool model can be enlarged/reduced and translated.

1. Relay control: Read the experimental instructions and enter the experiment. By reading the circuit diagram, select relays, thermal relays, switches and other components in the component list and drag and drop them into the electrical cabinet. The limiter is placed on the three-dimensional machine tool model. You can choose to cover the cover. Some component names can be renamed. Then click the connect line button to connect the terminals. After the machine tool circuit is successfully connected, choose to turn on the power and operate. If the component or line connection is wrong, an error box will pop up. The scene can be reset at any time.

2. PLC control: The experiment is the same as relay control, and the PLC control function is added. After the connection is completed, enter the program writing interface through the PLC coding button. Write two forward and reverse programs. There are 12 ladder diagram symbols in total. After writing, select Submit for program verification. After successful verification, turn on the power to operate. If there are component, line connection, and code errors, an error box will pop up. The scene can be reset at any time.

3. Single-chip microcomputer control: The experiment is the same as relay control, with the addition of single-chip microcomputer control function. After the connection is completed, enter the programming interface through the C coding button, enter the correct C language code, submit and verify successfully, turn on the power to operate, and error boxes will pop up for components, line connections, and code errors, and the scene can be reset at any time.

Wechat scan code follow us

Wechat scan code follow us