1. Understand the structural characteristics and differences in heat transfer performance of plate, shell and tube and shell and tube heat exchangers.

2. Master the performance testing methods of each heat exchanger and understand the factors that affect the performance of the heat exchanger.

3. Deepen the understanding of the difference in heat transfer capacity between co-current and counter-current flow modes of heat exchangers.

4. Master the measurement techniques of fluid flow rate, flow, pressure, temperature and other parameters.

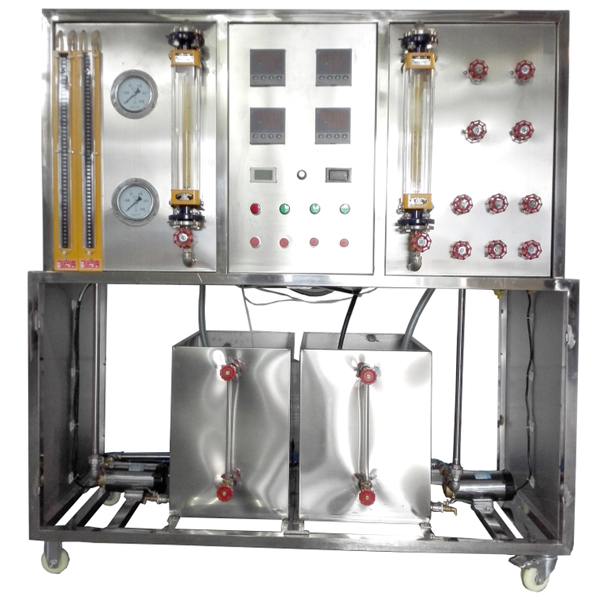

M*n configuration:

Shell and tube heat exchanger, plate heat exchanger, shell and tube heat exchanger, cold and hot water anti-corrosion water pumps, cold and hot water rotor flowmeters, cold and hot water st*nless steel raw water tanks and heating water tanks, forward and reverse flow regulating valve groups, resistance test pressure gauge and U-type differential pressure gauge, heating power is steplessly adjusted by solid pressure regulating module, universal signal input inspection instrument displays temperature, ammeter, voltmeter, st*nless steel stand and control panel, etc.

Technical Parameters:

1. Input power: three-phase AC380V±10% 50Hz, power 6.5KW.

2. Heat exchanger area: shell and tube heat exchanger 0.36m2, plate heat exchanger 0.56m2, shell and tube heat exchanger 0.21m2.

3. Total electric heating power: ≦6.0KW, heating temperature: ≤80℃.

4. Parameters of cold and hot water pumps: flow rate: 20L/min, head: 12m, power: 120W.

5. Rotor flowmeter: two in parallel, hot water flow range: 16-160L/h, cold water flow range: 40-400L/h.

6. Raw water tank: 304 st*nless steel, capacity: 80L (the cold water tank is sealed with a cover to prevent dust from falling, and is equipped with a liquid level display device; the water tank inlet is equipped with a float valve to ensure a constant water level in the tank).

7. Hot water tank: 304 st*nless steel, capacity: 60L (the hot water tank is sealed with a cover, independent of the cold water tank, and equipped with a liquid level display device).

8. Temperature measurement: The measurement system is equipped with an intelligent temperature control instrument (PID temperature control, accuracy ±0.2°C) and a high-precision PID voltage regulation module circuit.

9. Overall dimensions: 1200×600×1700mm, with st*nless steel movable bracket and double brake wheels.

Note: It can be upgraded to intelligent data collection type.

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap