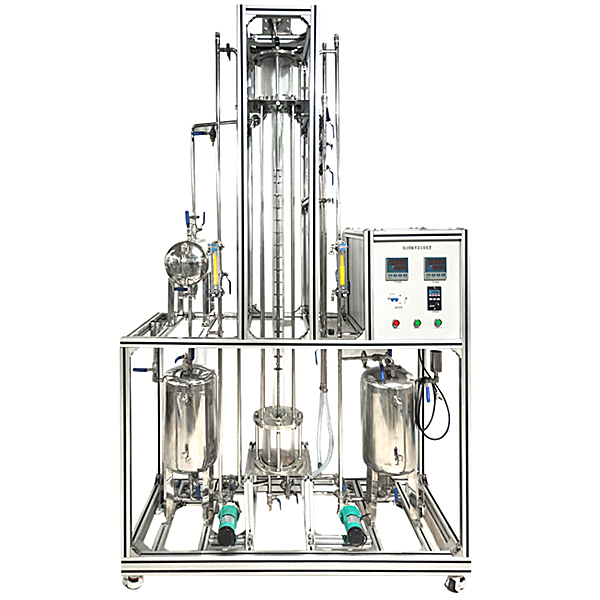

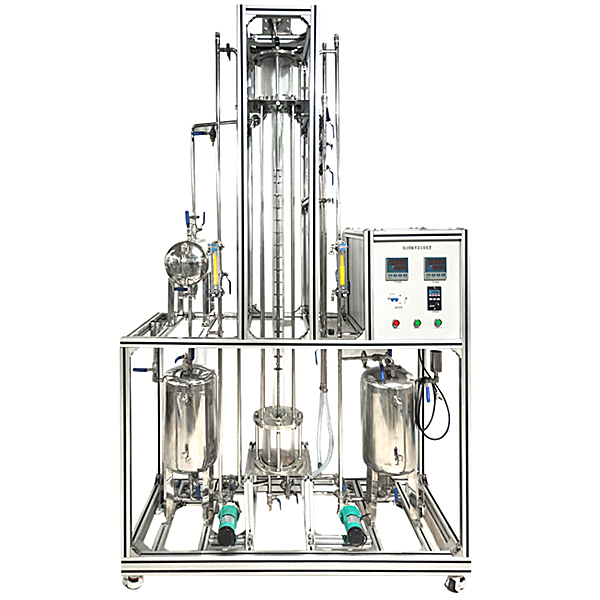

Dyhgyl-16 vibration sieve board extraction training platform

Release time:2024-06-07 05:30viewed:times

Features of the device:

1. The entire device is beautiful and elegant, with reasonable structural design and strong sense of integrity, which can fully embody the concept of modern experimental devices.

2. The entire equipment is a self-propelled frame structure and is equipped with restr*ning feet to facilitate the disassembly, m*ntenance and transportation of the system.

3. Except for special materials, the entire set of equipment is made of industrial 304 st*nless steel. All equipment is finely polished, which reflects the process perfection of the entire device.

4. The tower sections are made of high-quality inorganic glass, which has good visual effects and is convenient for students to observe.

5. The components and pipes inside the tower are made of 304 st*nless steel.

6. The device design allows for 360-degree observation, enabling all-round teaching and experimentation.

7. It can monitor the original experimental data online and display the data curve. Equipped with a true color TFT touch screen with RS485 interface, data can be exported through a USB flash drive and can be connected to a printer to print data. The device can realize manual and automatic interference-free switching operations, and is equipped with safety interlock protection and automatic alarm devices to ensure normal operation of the equipment and prevent safety accidents.

Device functions:

1. Understand the structure and application of the vibrating sieve plate extraction experimental device.

2. Determine the extraction efficiency.

3. Master the relationship between vibration frequency and extraction efficiency.

4. Full touch integrated control, highly stable data transmission, and hardware encryption.

5. The device can scan the code with a mobile terminal to obt*n a video introduction to the device process.

Design parameters:

normal temperature and normal pressure operation.

Extraction tower rotation frequency: 20-250r/min.

Number of mass transfer units NOE: 0.4-3.0.

Mass transfer unit height HOE: 0.3-2.0m.

Volume total mass transfer coefficient, KYea: 2.0×104--2.0×105 kgA/[m3.h.(kgA/kgs)].

Water flow: 1.6~16L/h.

Kerosene flow rate: 1.6~16L/h.

Utilities:

Water: The device comes with a 304 st*nless steel water tank, which is connected to tap water.

Electricity: voltage AC220V, power 1.0KW, standard single-phase three-wire system. Each laboratory needs to be equipped with 1~2 grounding points (safety ground and signal ground).

Experimental materials: water-kerosene-benzoic acid.

External equipment and medicines: kerosene-benzoic acid, Na(OH)2 standard solution, chemical analyzer. (Prepared by user)

M*n equipment:

1. The extraction tower is entirely made of glass. The diameter is φ45mm and the height is 1200mm. It consists of a total of 20 sieve plates, which are fixed with screws around them. The whole process of the experiment can be well observed.

2. Positioner: inverted U shape, diameter φ10mm, made of 304 st*nless steel.

3. Adjustable speed motor : voltage AC220V, power 60W, the vibration speed of the motor is adjusted by the speed regulator and the frequency converter.

4. Flowmeter: Metal remote transmission rotor flowmeter, flow range 1.6~16 L/h, 4-20mA remote transmission output, flow detection mechanism . Quantity: 2 pieces.

5. Measure the speed sensor : Hall switch.

6. Raw material tank: 20L volume, 304 sanitary grade st*nless steel.

7. Extraction phase tank: volume 20L, 304 sanitary grade st*nless steel.

8. Refined phase tank: volume 20L, 304 sanitary grade st*nless steel.

9. Pt100 thermal resistance thermometer: 0-100℃.

10. MP type magnetic drive pump (two units): power 30W, head 8m.

11. Electrical appliances: contactors, switches, leakage protection *r switches.

12. 304 st*nless steel pipes, fittings and valves.

13. Central processor: execution speed 0.64μs, memory capacity 16K; built-in RS485 communication mode; function: temperature, pressure and other analog signal acquisition and conversion;

14. Analog module: up to 16-bit resolution, total accuracy ±0.5%;

15. Temperature module: resolution 0.1℃, accuracy 0.5%; function: temperature signal collection and conversion;

16. Using an all-in-one tablet touch computer, the entire process is controlled by a digital touch screen. HMI: Projected touch technology, 50 million touch points, 2G memory, function: central processor data display control;

17. Rated voltage: 380V, total power: 15kW;

18. Overall dimensions: 1500×550×1800mm (length × width

19. Engineering signs: including equipment tags, pipeline flow direction arrows and logos, valve tags and other engineering equipment concepts, including safety warning signs, so that students can be in a safe experimental operating environment and learn to recognize engineering pipeline signs. knowledge and cultivate students’ engineering concepts.

20. Virtual simulation software for electrical installation of building buildings and smart buildings. Based on unity3d design, users can choose different interactive interface sizes according to computer configuration, and six levels of image quality are av*lable. In-software model

Can perform 360° rotation, zoom in, zoom out, and pan. There are assistant prompts during the use of the software, and the content is as follows:

A. Wet alarm system

1. System overview: Overview of wet alarm system

2. Equipment awareness: equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), and exercises (Built-in 6 multiple-choice questions, prompts for correct and incorrect choices), schematic diagram (can be entered into the device from the schematic diagram). Equipment includes: nozzle, water flow indicator, signal butterfly valve, exhaust valve, fire alarm control, high pipe pressure gauge, high water tank, Wia control cabinet, pressure stabilizing tank, flow switch, terminal water testing device, dr*nage facilities, water pump connection alarms, hydraulic alarms, delayers, wet alarms, butterfly valves, check valves, fire pumps, safety pressure regulators, and fire pools.

3. Principle display: Show the working principle of the wet alarm system, three-dimensional animation demonstration, the three-dimensional model is translucent, and the internal water flow can be seen. Equipped with a practice module (built-in 4 multiple-choice questions, with prompts for correct and incorrect choices)

4. Design layout: There are multiple-choice questions and calculation questions, each question is scored, and the correct answer and score will be displayed after submission

B. Gas fire extinguishing system

1. System overview: Overview of gas fire extinguishing system

2. Equipment awareness: equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (built-in 8 multiple-choice questions, with prompts for correct and incorrect choices), Schematic diagram (access to the device from the schematic diagram). Equipment includes: nozzle, HFC-227 storage bottle, bottle head valve, heptafluoropropane one-way valve, high-pressure hose, gas one-way valve, safety valve, weighing alarm, electromagnetic starter, selection valve, smoke alarm, fire Alarm controller.

3. Principle display: Demonstrate the working principle of the gas fire extinguishing system, three-dimensional animation demonstration, the three-dimensional model is translucent, and the internal gas can be seen. Equipped with a practice module (built-in 3 multiple-choice questions, with prompts for both correct and incorrect choices)

4. Design layout: There are 6 multiple-choice questions, each question is scored, and the correct answer and score will be displayed after submission.

C. Escape drill: adopted Teaching is conducted in the form of fun games. Escape from the burning room within a limited time. If you make a wrong choice, you will directly enter the score interface.

Wechat scan code follow us

Wechat scan code follow us