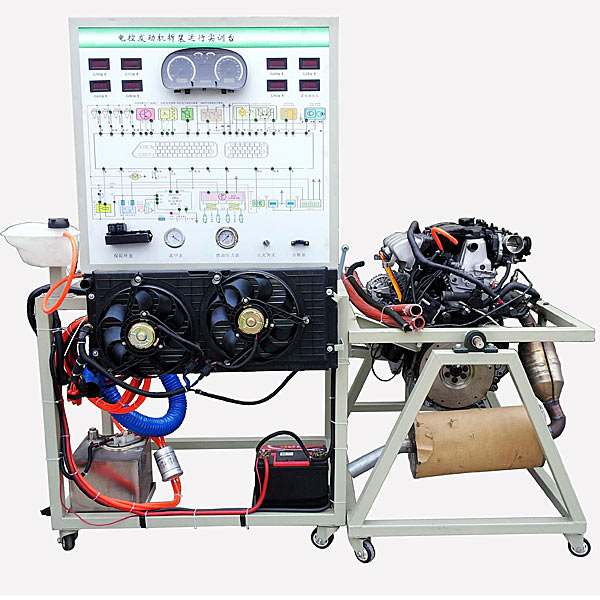

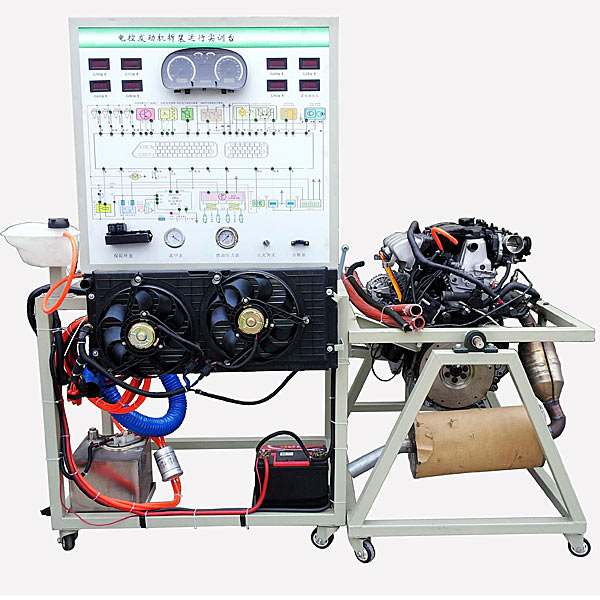

| serial number | name | Specifications and models | unit | quantity | |

| (1) 1 set of operation detection console | |||||

| 1 | Test control panel |

Equipped with various detection terminals and color circuit diagram (950*900*4mm aluminum-plastic plate) |

set | 1 | |

| 2 | Engine control computer (ECU) | Original car | set | 1 | |

| 3 | instrument cluster | Original car | set | 1 | |

| 4 | Diagnostic seat | Original car | indivual | 1 | |

| 5 | Ignition switch assembly | Original car | indivual | 1 | |

| 6 | fuel pressure gauge | 0-10kg/cm2 | indivual | 1 | |

| 7 | Vacuum pressure gauge | 0-76in.Hg | indivual | 1 | |

| 8 | Fuel tank | 10L | indivual | 1 | |

| 9 | Gasoline pump (including gasoline pump plug) | brand new | set | 1 | |

| 10 | Water tank and accessories | Original car | set | 1 | |

| 11 | cooling electronic fan | 12V, 80W | indivual | 2 | |

| 12 | battery | 12V 65Ah | tower | 1 | |

| 13 | relay | Including: starting relay, oil pump relay, cooling fan relay, etc. | set | 1 | |

| 14 | Butt harness | set | 1 | ||

| 15 | Fuse box | indivual | 1 | ||

| 16 | m*n power switch | 50A | indivual | 1 | |

| 17 | Mobile stand (with self-locking casters, panel cabinet and base) |

1000*700*1750mm (length*width*height) |

tower | 1 | |

| 18 | Fault simulation and troubleshooting device | set | 1 | ||

| (2) 1 set of disassembly and assembly flip stand | |||||

| 1 | Electronically controlled gasoline engine assembly | Original car | set | 1 | |

| 2 | Intake and exhaust pipes | Original car | set | 1 | |

| 3 | three way catalytic converter | With new muffler | set | 1 | |

| 4 | Butt harness | set | 1 | ||

| 5 | Large area oil basin | About 700×650×30mm (length×width×depth) | indivual | 1 | |

| 6 | Disassembly and assembly of flip stand (with self-locking caster device) | Approximately 1300×600×800mm (length×width×height), with reducer, capable of flipping and stationary at any angle in the axial direction. | set | 1 | |

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap