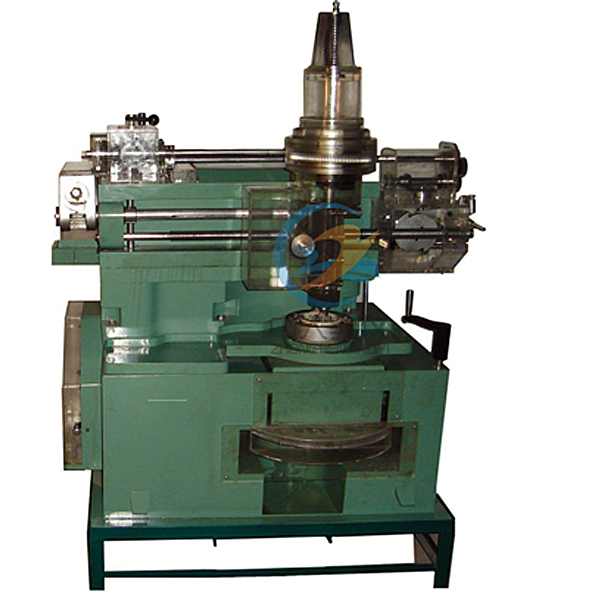

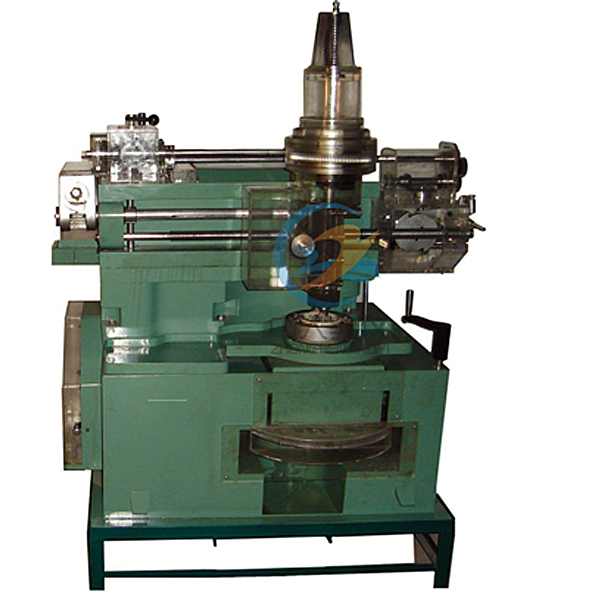

dyjx-cch transparent teeth training device

Release time:2024-05-18 02:30viewed:times

1. Product Features

1. This product is made of transparent organic glass, and the parts are made of aluminum. The internal structure and movement of the product can be seen completely transparently.

2. All anatomical components can perform normal mechanical operation.

3. Fully display each minute structure and mechanism assembly device.

4. Automatically operate and deduce the product operation process, allowing students to intuitively understand the overall process.

5. The product as a whole looks beautiful and elegant, the image is lifelike, the components are clearly distributed and clear at a glance, the specific rotation is flexible, and the demonstration is convenient.

6. This model is a non-standard product. Its m*n operating performance is somewhat different from the real thing. Its rigidity and strength cannot be compared with the real machine tool. It is a relatively intuitive help for students to understand the transmission system and external structure of the gear hobbing machine.

2. Product description

Model production is essentially different from the real thing in terms of material use and accuracy standards. The gear hobbing machine model produced by our company is made at a ratio of 1:0.75 of the real thing. It is the result of our factory’s production practice and the feedback from schools and teachers. Satisfactory production ratio.

3. Technical parameters

1. Overall dimensions: (length × width × height) 1600mm × 700mm × 1300mm.

2. The maximum stroke of the tool holder slide is 180mm, and the maximum processing diameter is 350MM.

3. The minimum distance between the hob spindle and the center line of the workpiece is 60MM.

4. Spindle motor power: 0.75 kilowatts.

4. Operation method

1. Before starting the machine tool model, please carefully check whether the gears of each part are in normal meshing.

2. Add an appropriate amount of lubricating oil (engine oil, butter) to each moving part.

3. Turn on the m*n power switch and check whether the m*n motor and fast motor are operating normally (pay attention to the forward and reverse directions and follow the arrow instructions).

4. Disengage the clutch on the right control box, insert the square head shaft with the rocking hand provided by our company, and shake it clockwise to drive the cam to move the tool holder to the right (up to the highest point of the cam).

5. Tool setting: At this time, the spindle should be in the lowest position (the shaft where the gear shaping cutter is installed). Use a rocking hand to insert the square head shaft on the tool holder and shake it clockwise so that the top point of the gear shaping cutter just touches the highest point of the workpiece. Edge (end face).

6. Tool feed: At this time, the dial on the tool holder should be set to 0 (note: one rotation is 3mm, one step is 0.03mm), and then move a cert*n depth to the right according to the module size of the tool (note: The module of the tool × 2.25), the tool equipped by our company is m=2.75, the corresponding depth is: 2.75×2.25=6.18mm, turn 2 times to pass 6 small grids.

7. Knife retraction: At this time, use a rocker to insert the square head shaft of the control box and shake it clockwise so that the roller of the moving shaft falls into the lowest position of the cam.

Wechat scan code follow us

Wechat scan code follow us