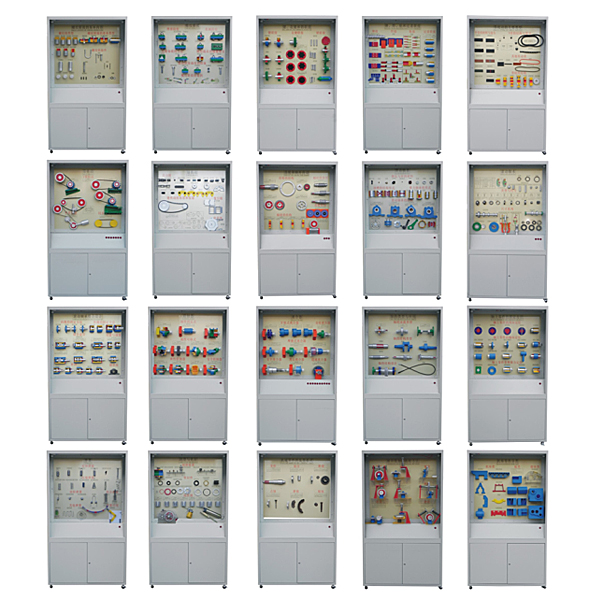

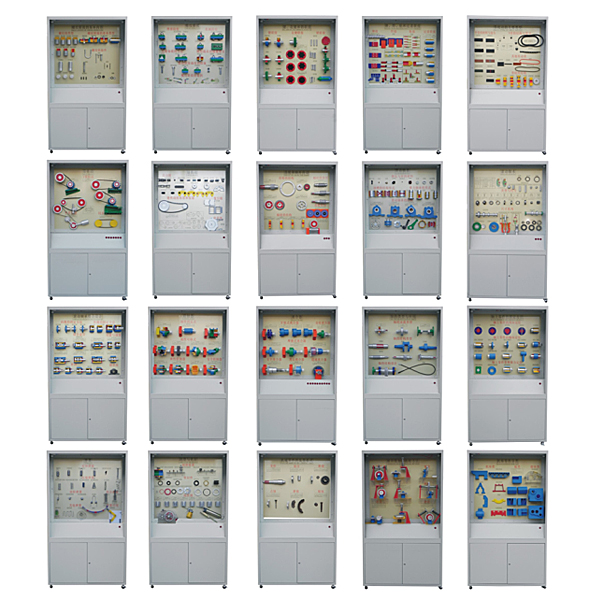

| Serial number and name | Display case contents |

|

Cabinet 1: Basic contents of threaded connections |

Thread types: ordinary thread, trapezoidal thread, rectangular thread, zigzag thread, arc pipe thread, cylindrical pipe thread, conical pipe thread, right-hand thread, left-hand thread, double thread, triple thread. Types of threaded connections: bolted connection, stud connection, screw connection, fastening screw connection. 11 bolts, 4 studs, 9 screws, 5 set screws, 12 nuts, and 7 washers. |

|

Second cabinet threaded connection |

Friction and anti-loosening: top nut, locking hot ring closing anti-loosening nut, slit closing, with nylon ring anti-loosening nut and spring washer. Mechanical anti-loosening: stop washer, stop washer ring and round nut, cotter pin and hexagonal slotted nut, series wire. Load relief devices for transverse load interception: inclined washers, bosses, countersunk pits, load relief sleeves, load relief keys, and interception relief pins. Measures to improve the connection strength: add elastic components, internally inclined nuts, hollow bolts, w*st-shaped rod bolts, large fillet bolts, undercut nuts, and assembly and disassembly of threaded connections. |

|

Cabinet 3 Key, spline and pin connection |

Key connection: ordinary flat key, semicircular key, wedge key, guide flat key, tangential key, saddle sliding key. Spline connection: 3 pieces of rectangular splines, 2 pieces of involute splines. Triangular spline. Pin connection: 3 pieces of cylindrical pins, 4 pieces of conical pins, 3 pieces of guide pins, 3 pieces of safety pins, positioning, connection, safety. |

|

Cabinet 4: Riveting, welding, gluing and interference joints |

Riveting: commonly used rivet types, lap joints, single lap plate butt joints, double lap plate butt joints, and combined joints. Welding: groove type, lap joint, butt joint, corner joint. Bonding: plate joint, pipe joint, corner joint. Interference connection: cylindrical interference connection, conical interference connection. |

|

The m*n types of belt drives in the fifth cabinet |

Materials and joints of flat belts: leather belts, br*ded belts, canvas flat belts, high-speed ring tapes, nylon sheet composite belts, bevel joints, bevel step joints, tape joints, suture joints, leather thread joints. The structure and model of V-belts: O-type, A-type, B-type, C-type, D-type, E-type, wide V-belt, narrow V-belt, flexible V-belt, other transmission belts, combined V-belt, ordinary V-belt, double Surface V-belt, multi-V belt, round belt, trapezoidal toothed synchronous belt. The structure of the pulley: solid pulley, spoked pulley, orifice pulley, elliptical spoked pulley, flat pulley, high-speed pulley, synchronous pulley. |

|

Cabinet Sixth Belt Drive |

V-belt transmission: automatic tensioning device, slide type periodic tensioning device, swing frame type periodic tensioning device, tensioning wheel tensioning device. Flat belt drive: tensioner device, synchronous belt drive |

|

The seventh cabinet ch*n drive |

Transmission ch*n: roller ch*n, inner ch*n plate and sleeve, roller, outer ch*n plate pin, inner ch*n plate, outer ch*n plate, single-pitch double-row roller ch*n, single-row single-pitch roller ch*n, spring Type, spring ret*ning ring, steel wire, cotter pin, transition link, integral sprocket with strap, integral plate type, hole plate type, toothed ch*n with inner guide piece, toothed ch*n with outer guide piece, round pin type, Arrangement and tensioning of roller type, key column type, bearing type, square ch*n, flat top ch*n, circular ch*n and ch*n drive. |

|

Cabinet Eight Gear and Worm Transmission |

The structure of the gear: 2 gear shafts, 2 solid gears, 2 web gears, and spoke gears. Types of worms: Archimedean cylindrical worm, normal str*ght profile worm, linear toroidal worm. The structure of the worm: integral worm gear, hoop worm gear, bolted worm gear, cast-in worm gear, worm drive, gear drive . |

|

Cabinet 9 Sliding Bearing |

Materials of bearing bush and lining: bearing alloy, bronze, brass, gray cast iron, miniature bearing, rubber, nylon, PTFE, phenolic resin. The structural form of the oil tank is 5 pieces, and the form of the push bearing: solid, hollow, single ring, multi-ring. The structure of the sliding shaft: overall lined positive sliding bearing, split positive sliding bearing, split oblique sliding bearing, self-aligning sliding bearing, fixed pad thrust bearing, self-aligning sliding bearing, tiltable three-reverse bearing, Connecting rod, hydrostatic bearing. |

|

Cabinet 10 Rolling Bearings |

Inner ring, cage, outer ring, balls, short cylindrical rollers, long cylindrical rollers, threaded rollers, tapered rollers, drum rollers, needle rollers. Types and codes: deep groove ball bearings, spherical ball bearings, spherical roller bearings, cylindrical roller bearings, needle roller bearings, spiral roller bearings, angular contact bearings, tapered roller bearings, thrust ball bearings, thrust rollers bearings. Dimension series: diameter series, inner ring fixed and outer ring rotating, outer ring fixed and inner ring rotating, rolling bearing installation method, rolling bearing disassembly process, inner diameter series 7 pieces, width series 4 pieces. |

|

Cabinet 11 Rolling bearing combination design |

Fixing methods of the inner ring: spring ret*ning ring, shaft end pressure plate, round nut, tapered sleeve. The fixing method of the outer ring: bearing end cover, elastic ret*ning ring for the hole, end cover hole shoulder combination, and sleeve cup. Combination design: 3 pieces with fixed ends, 2 pieces with both ends moving, and 2 pieces with one end fixed and one free. Tightening and adjustment: adjustment of rolling bearings and tightening of rolling bearings. Seals: Felt type, cup type, annular gap type, labyrinth type, thread type, bearing seat |

|

Cabinet 12 Coupling |

Elastic sleeve pin coupling, elastic pin coupling, tire coupling, flange coupling, sleeve coupling, clamp coupling, gear coupling, ch*n coupling, cross Axis universal coupling, slider coupling, shear pin safety coupling. |

|

Cabinet Thirteen Clutch |

Teeth clutches include rectangular teeth, trapezoids, equilateral triangle teeth, sawtooth clutches, single disc friction clutches, conical friction clutches, multi-disc friction clutches, tooth-type safety clutches, centrifugal clutches, and overrunning clutches. |

|

Cabinet 14 Types and Applications of Shafts |

Structural design of rotating shafts, spindles, drive shafts, gear shafts, key shafts, worm shafts, crankshafts, camshafts, flexible shafts, and shafts . |

|

Cabinet 15: How to fix parts on the shaft |

Key connection, spline connection, formed connection, pin connection, interference connection, shoulder - circlip, shoulder - round nut, shoulder - double round nut, shoulder - sleeve, shoulder - circlip 2 Year, conical shaft head - shaft end ret*ning ring, shaft end ret*ning plate, double locking ret*ning ring, slotted clamping connection, hub part clamping connection, elastic sleeve connection, elastic ring connection, elastic disk connection. |

|

Cabinet 16 Spring |

Tension springs: circular shackle, semi-circular shackle, eccentric circular shackle, tapered closed end spring, adjustable tension spring. Compression springs: springs with flattened end faces, springs with unflattened end faces, rectangular cross-section compression springs, convex springs, concave springs, and conical spiral springs. Torsion springs: outer arm torsion spring, inner arm torsion spring, center arm torsion spring, double torsion spring. Other springs: disc springs, serpentine springs, flat scroll springs, leaf springs. Parallel combination spring, in-line combination spring, conversion mechanism. |

|

Cabinet 17 Lubrication and sealing |

Lubrication device: press-fit pressure oil cup, oil rope type cup, joint type pressure oil cup, str*ght-through oil cup, oil mark. Seals: 2 pieces of O-type rubber seals, 2 pieces of rectangular rubber seals, nylon gaskets, asbestos gaskets, metal flat gaskets, metal octagonal gaskets, metal toothed gaskets, cutouts: insert lap joints, piston rings , Cut: oblique overlap, double-port oil seal, T-type oil seal, Y-type oil seal, V-type oil seal. 8 pieces of lubricant, oil gun, butter gun. |

|

Cabinet 18 F*lure modes of mechanical parts |

Gluing, fracture, corrosion, wear, pitting, residual deformation |

|

Cabinet 19: Involute machining method for gears |

2 pieces of gears are processed by profiling, 2 pieces of gears are machined with hobs, 2 pieces of teeth are machined with gear shaper, gears are machined with rack shaper, gears are machined with planers , gears are shaving, and gears are rubbed with disc grinding wheels |

|

Cabinet 20 Machine Base Parts Classification |

Horizontal machine base, doorman machine base, vertical machine base, ring machine base, truss machine base, frame machine base, frame machine base, base and base plate, bench type support, plate support plate Arrange 7 pieces, 2 pieces of reducer box and gearbox box. |

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap