| 1 |

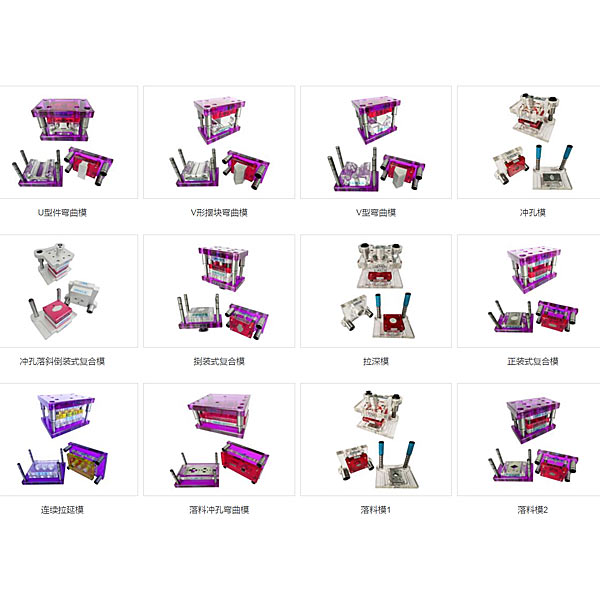

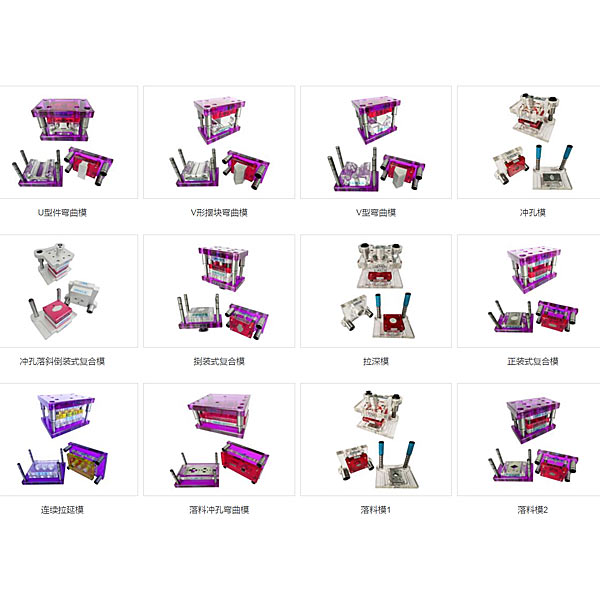

Punching die XSTMFZCM-001 150×150mm |

1 set |

Use the die to punch the plate along the closed line. The punched part is scrap, and the product is outside the closed line. One hole is punched, and the material strip is positioned using four stopper pins. |

| 2 |

Blanking die XSTMFZCM-002 150×150mm |

1 set |

Use a die to punch along a closed contour curve. The product is inside the closed line, and the scrap is outside the closed line. It is used to manufacture flat parts of various shapes. For stamping diamond-shaped workpieces, the product size is not less than 35×30 mm, and the material strip uses stopper pins position. |

| 3 |

Bending mold XSTMFZCM-003 150×150mm |

1 set |

By bending plate materials into various shapes along straight lines, parts with more complex shapes can be processed. The diamond-shaped workpiece is used as the guide material, the bending height is not less than 10 mm, and the product automatically falls off from the punch. |

| 4 |

Formal composite mold XSTMFZCM-004 200×150mm |

1 set | A mold that can complete several different punching processes at the same position of the mold. Formal composite mold, its blanking and concave molds are installed at the lower mold, and the convex and concave molds are installed at the upper mold. It is not suitable for punching and punching diamond-shaped porous parts. The workpiece and the material strip are positioned using stopper pins. |

| 5 |

Flip chip composite mold XSTMFZCM-005 200×150mm |

1 set | A mold that can complete several different loading processes at the same position of the mold. A flip-chip composite mold has the blanking die at the upper die and the convex and concave dies at the lower die. It is suitable for thick and thick parts that do not require high straightness. Plate parts, easy to operate and safe, suitable for punching porous parts. Stamping diamond-shaped workpieces, the material belt is positioned by stopper pins. |

| 6 |

Stretching die XSTMFZCM-006 150×150mm |

1 set |

A mold for forming blanks of plate materials into hollow workpieces with various openings. This mold is equipped with a blanking device. Before drawing, the blank is placed on the blanking ring and positioned by its shape. After drawing, the cold stamped parts are lifted out from the punch. The convex and concave molds All are equipped with ejection devices. Stretching small aluminum covers, the drawing depth is not less than 8 mm, the product size is not less than 35 mm, the mold has a pressing structure, and the adjustment is very convenient. |

| 7 |

Continuous drawing die XSTMFZCM-007 200×150mm |

1 set |

The product cannot be formed after the first deep drawing and requires multiple drawings of the mold. The mold uses one end of the strip to draw sequentially, and the part is flushed off the strip until the last drawing. Drawing a small aluminum cover with a flange, the drawing depth is not less than 8 mm, the product size is not less than 20mm, the first drawing depth is not less than 2 mm, the mold has a pressing structure, and the adjustment is very convenient. |

| 8 |

Multi-station progressive die XSTMFZCM-008 200×150mm |

1 set |

The multi-station progressive die is a precision, high-efficiency, long-life mold. It is suitable for cold stamping small-sized, thin materials, complex shapes and mass-produced cold stamped parts. The mold is a progressive die for blanking, punching, and bending . , the wool is positioned throughout the entire process by positioning pins and stopper pins, with a 90-degree bend, and the size is not less than 20×15×10 mm. |

| 9 |

V-type flap bending mold XSCZFZCM-009 150×150mm |

1 set | In order to prevent the material from sliding, the mold has two flaps at the top of the fixed mold part. When the punch is pressed, the flap bends with the material, and the positioning plate must be in contact with the material, so the precision of the formed parts is high. The size of V-shaped parts is not less than 30×20×10 mm. |

| 10 |

Round tube punching die XSCZFZCM-010 150×150mm |

1 set | This mold requires bending a flat blank into a circular tube-shaped part at one time. The fixed mold has two movable concave molds supported by the top plate. When the punch presses the material down, the modules rotate toward each other and bend the material into a circle. When the punch rises, the bent circular tube part is placed on it and rises accordingly. The size of round parts is not less than Ф17×30 mm. |

| 11 |

Type slider die XSCZFZCM-011 150×100mm |

1 set | This mold needs to bend the flat blank into parts with two inner side angles less than 90° at one time. The fixed mold part of the mold requires two slide blocks. The flat blank is placed on the positioning plate. When the punch descends, the flat blank is first bent into a ∪ shape. The convex continues to descend, and the slide blocks start to move both sides of the ∪ shape inward. Bend to desired angle. The size of the parts is 45×30×20 mm. |

| N0 | Configuration name | quantity | Detailed description and technical requirements |

| 1 |

Fine nozzle mold XSCZZM-001 200×200mm |

1 set | The mold has a gate with a cross-sectional shape as small as a pin point, which can increase the shear rate of the melt and improve the fluidity of the melt, which is beneficial to mold filling. The gate mark is small and easy to trim, and the gate position can be selected more freely. The mold structure is one mold with two cavities. The molded product is a mobile phone case with a cavity of 70×30㎜. The total weight is 20 grams, with one-point glue feeding. |

| 2 |

Secondary ejection mold XSCZZM-002 200×200mm |

1 set |

For molding plastic parts with deep cavities, thin walls, complex side shapes and large demoulding force, the ejection mechanism can eject them twice in succession. The structure is simple, easy to process, safe and reliable. The molded product is a heart-shaped soap dish with a molding size of 50×55×12㎜. |

| 3 |

Front mold Huff mold XSCZZM-003 200×200mm |

1 set |

It is used for plastic parts with large side forming area, shallow side holes or undercuts and small extraction distance (such as turning molds and external thread molds) with compact structure, good rigidity and large extraction force. The molded product is a coffee cup with a handle, measuring 26×30㎜. |

| 4 |

Front mold row position mold XSCZZM-006 200×200mm |

1 set |

Plastic parts have high requirements on appearance, and the fixed mold needs to be equipped with a core-pulling mechanism. The mold has a compact structure, strong rigidity, safety and reliability, and is widely used in large molds. The molded product is an alarm clock case with a molding size of 60×50×10㎜. |

| 5 |

Diving mouth mold XSCZZM-007 200×200mm |

1 set | The mold can not only automatically cut off the gate when opening the mold, but also the gate can be positioned on the side, end face and back of the product, so that there are no traces of the gate on the outer surface of the product. The latent gate mold structure can be used to simplify the double-parting surface mold structure into a single-parting surface mold structure. One mold with two cavities, and the runner is automatically separated from the product. |

| 6 |

Inclined top mold XSCZZM-011 200×200mm |

1 set | The molded plastic parts with concave and convex inside are easy to process, compact in structure and reliable. The oblique push rod cooperates with the guide groove. When the push rod moves vertically, the oblique push rod makes relative movement under the action of the guide groove, thereby completing the side core pulling action. . One mold has two cavities, and the inner wall has two concave or convex grooves, which can be assembled together. The molding size is 50×90×10㎜. |

| 7 |

Hot runner mold XSCZZM-012 200×200mm |

1 set |

Hot runner molds use thermal insulation or heating methods in the injection mold to keep the plastic in the runner in a molten state. Therefore, when opening the mold, you only need to take out the plastic product without a runner mold structure. One mold and two cavities, computer automatically controls the temperature and the heating time does not exceed 15 minutes. It can realize runner-less production, and the product is automatically cut off at the gate. The size of the molded mobile phone case is 60×30×8㎜. |

| 8 |

Rear mold oblique core-pulling mold XSCZZM-016 200×200mm |

1 set |

There is an oblique groove on the inside of the plastic product formed by the mold. The mold adopts a fixed template hook and swing bar type sequential parting mechanism, and a push rod is used to push out the product. The purpose of sequential parting is to complete lateral oblique core pulling. There are two 45-degree perforations on the inside of the molded product, and the mold is divided twice to complete the oblique core pulling. The molding size is 30×20×10㎜. |

| 9 |

Push plate mold XSCZZM-017 200×200mm |

1 set | The push plate demoulding mechanism pushes the product out along the periphery of the product at the parting surface, and is suitable for demoulding large tube products, thin-walled containers and various shell products. Its characteristics include uniform pushing force, smooth movement, the product is not easily deformed, and there are no push marks on the surface of the plastic parts. The molded product is a mini tea cup, with one mold and two cavities, and a push plate for ejection. The product diameter is 20 mm and the height is 16 mm. |

| 10 |

Inclined guide column mold XSCZZM-018 200×200mm |

1 set | The structure is compact, easy to manufacture and reliable in action. Its structural form is that the inclined guide pillar forms a certain angle with the mold opening direction. Under the action of the mold opening force, the inclined guide pillar and the slider material hole move relative to each other, thereby completing the side core pulling action. The molded product is a button belt, with a total of 2 perforations on both sides of the product, a slider and an inclined guide pillar for core pulling. The molded product has a cap size of 25×20×18㎜ |

| 11 |

Ejector first reset mold XSCZZM -019 200×200mm |

1 set | When there is interference between the side core puller and the push rod or when it is inconvenient to place the insert, the ejection system is reset in advance through mechanical components. The molded product is a tie buckle with a molding size of 35×30×10mm. The mold has a beautiful appearance and is very convenient for reset and correction. |

| 12 |

Rotary tooth pattern mold XSCZZM-020 200×200mm |

1 set | It is a production method for molding deep-pitch, threaded plastic parts of hard materials, and achieving demoulding through relative rotation between the product and the threaded core or ring-shaped product in the mold. The molded product is a bottle cap, with one mold and two cavities. The product size is 20×15 mm, the pitch is 3, the matching thread depth is 10mm, and the number of single-cavity threads is 3. Main channel floating ejection structure, time control of demoulding process. |

| 13 |

Push tube mold XSCZZM-021 200×200mm |

1 set | Push tube molds are often used for demoulding cylindrical products. The push tube pushes the product along the entire periphery, so that the product is evenly stressed and has no push-out marks. The core and the concave mold are both located on one side of the movable mold to improve the coaxiality of the product. The molded product is a conical cup with one mold and two cavities, and the size is 25×15 mm. |

| 14 |

Elbow mold XSCZZM-026 200×200mm |

1 set | The mold structure for core-pulling within the arc of an elbow often uses mechanical structural parts such as gears, racks, or connecting rods to convert linear motion into a structural form of circular motion, thereby achieving the purpose of arc core-pulling. |

| 15 |

Rear mold position mold XSNZS-029 200×200mm |

1 set |

Plastic parts have high requirements for appearance, have grooves on the inner wall, and cannot have a sloped roof structure. The fixed mold needs to be equipped with an internal core-pulling mechanism. The mold has a compact structure, strong rigidity, safety and reliability, and is widely used in molds. The molded product is a mobile phone casing with a molding size of 60×50×10㎜. |

| 16 |

Chain forming mold XSCZZM -030 200×200mm |

1 set | The mold adopts 45° split molding, precise positioning of rows, and integrates functions such as point gates and inclined guide pillars to form a product with multiple interlocking circles. For the first time, four interlocking circles were formed, and the molded product was 125×26× 3mm. Through simple operation, the two circles can be interlocked twice to achieve infinite extension of the chain. It is one of the more typical structures in injection molds. |

| 17 |

Large row position hiding small row position mold XSCZZM-031 200×200mm |

1 set |

When opening the mold, the inclined guide posts drive the small rows within the large rows to move first. After the small rows are separated from the glue positions, the large rows are then moved. This is suitable for protruding side shapes, deep grooves and glue. Bits of plastic that are too thin. This product is in the shape of a box. There is a larger groove on one side of the product, and there is a convex groove in the groove that is not in the same direction. The size of the product is 60×35×20mm, and the core pulling depth is 8mm. |

| 18 |

Rear mold feeding flip-chip mold XSCZZM-032 200×200mm |

1 set |

The rear mold part of the mold is placed at the position of the front mold. Glue is fed from the direction of the rear mold, and the pull rod fixed on the front mold pulls the ejector plate to eject the product. It is suitable for molding parts with attached inserts on the surface or bright surfaces and large volumes. of plastic products. This product is a transparent reflective lampshade, and the product size is 60×35×20mm. The mold must have the following knowledge points. |

| 19 |

Explosive core mold XSCZZM -033 200×200mm |

1 set |

When the mold is closed, the insert moves along the oblique guide groove on the circular core, so that the periphery of the circular core reaches a closed state. This mold is suitable for plastic products that are round and have grooves inside the round. This product is cylindrical, with multiple rows of grooves inside the product. The grooves are perpendicular to the center line of the product. The glue feeding method adopts the glue feeding method from the center of the product. The size of this product is Ø42×35mm, and the number of sliders is 5. |

| 20 |

Two-color mold XSCZZM-034 200×200mm |

1 set |

The mold consists of one set of rear molds and two sets of front molds. After one set of front molds and the shared rear mold are used to injection mold the product, the product is then placed on the shared rear mold core, and another set of front molds and the shared rear mold are used for secondary molding. Injection molding is used to form glue spots of different colors or materials on the surface of the product. This product is a toothbrush handle. The punch is placed in the movable mold part of the mold, and the concave mold is interchangeable through an electromechanical moving platform. The mold design has a compact structure, stable movement, and high efficiency. It is the manufacturing trend of modern two-color molds. The product size is 60×25×20mm |

|

1. The mold has the function of disassembly and assembly training, and can be disassembled and assembled repeatedly for a long time. 2. It can be used for half-mold injection. During injection molding, you can clearly see the plastic flow in the mold cavity and fill the cavity. 3. The guide posts and guide sleeves are made of standard parts, and all bolts must be grade 12.9 bolts produced by well-known domestic and foreign companies. 4. The formwork is made of hardened aluminum alloy plates and has been oxidized, with a hardness of HB90 or above and a yield strength of 245 or above. |

|||

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap