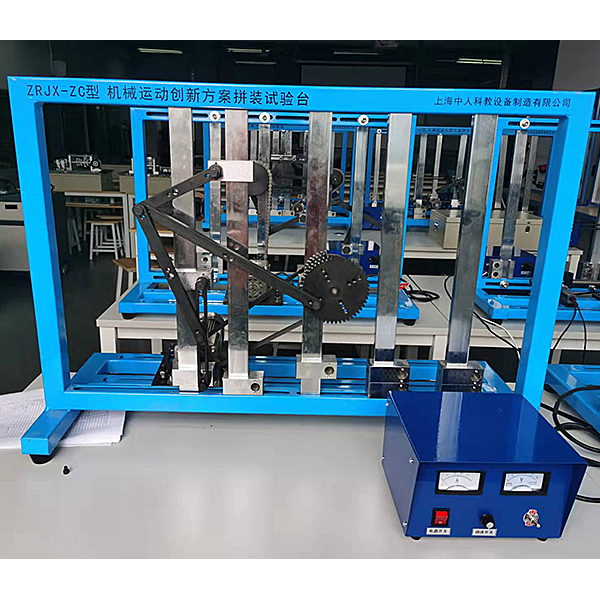

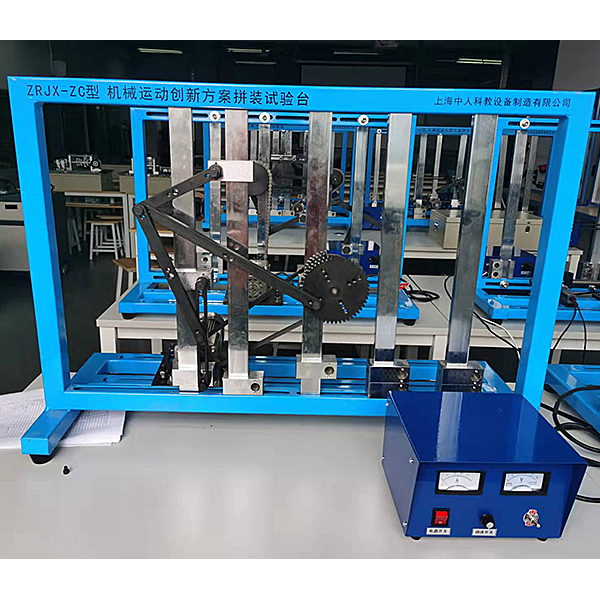

| 1. Guide rod rack and pinion mechanism; | 21. Six-bar mechanism; |

| 2. Multi-rod stroke amplification mechanism; | 22. Double swing rod swing angle amplification mechanism; |

| 3. The mechanism to realize a given trajectory; | 23. Rotate the guide rod and cam to enlarge the stroke mechanism; |

| 4. Packing press mechanism; | 24. Crane mechanism; |

| 5. Flying shear mechanism; | 25. Ingot feeding mechanism; |

| 6. Single-cylinder gasoline engine mechanism; | 26. Slotting machine slotting mechanism; |

| 7. Internal combustion engine mechanism; | 27. M*n transmission mechanism of gear shaping machine; |

| 8. Jaw crusher; | 28. Planer guide rod mechanism; |

| 9. Pump; | 29. Crank force-increasing mechanism; |

| 10.Photography lift; | 30. Combination of slider crank mechanism and rack and pinion mechanism; |

| 11. Reciprocating motion mechanism with approximately constant speed output; | 31. Crank rocker mechanism; |

| 12. The stroke mechanism can be expanded; | 32. Four-bar mechanism; |

| 13. Crank rocker type slotting mechanism; | 33. Crank slider mechanism; |

| 14. Sewing machine thread and needle guide mechanism; | 34. Crank slider feeding mechanism; |

| 15. Pressure gauge indicating mechanism; | 35. Crank rocker and rocker slider mechanism; |

| 16. Mixer mechanism; | 36. Sheave mechanism and guide rod mechanism; |

| 17. Paper feeder mechanism; | 37. Cam crane mechanism; |

| 18. Card feeding mechanism of card punching machine; | 38. Flat pressure grinding and cutting machine mechanism; |

| 19. Steam engine mechanism; | 39. The m*n disassembly mechanism of the forging press; |

| 20. Automatic lathe feeding mechanism; | 40. Double swing rod swing angle amplification mechanism; |

| 41. Crane mechanism, etc. |

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap