This device is a device that achieves multiple uses, resource sharing, and easy management. The PLC part simulates typical control objects in the actual industrial control process. It vividly demonstrates the entire execution process of PLC. Be able to vividly verify the correctness of the program you write with vivid execution mechanisms, master the practical application of PLC, and enhance students' interest in learning PLC. The product adopts a hanging box type, which facilitates the expansion of experimental projects and second development by users. Since the launch of the product, it has received unanimous pr*se from teachers and experts in major universities. The complete set of devices has reasonable design, powerful functions, simple and convenient operation, and helps students understand and master the control principles and operating methods of programmable controllers. Accelerate learning of PLC programming methods. All extremely helpful.

2. M*n equipment composition

(1) Logic control unit

Siemens S7-1200 programmable controller kit 1 set

1) Controller CPU integrated input/output: 14 digital inputs 24V DC input, 10 transistor outputs 24 V DC, 2 analog inputs 0 - 10V DC or 0 - 20mA; power supply: DC 24 V; programmable Datastore: 50 KB

2) Analog output module 1 analog output 12BIT +/- 10VDC / 0-20 mA

3) Simulator module 8 POSITION

4) Ethernet cable

5) Engineering configuration software wincc (including authorization)

6) Digital input and output module 8 input 24V DC/ 8 output relay

Power module, input: 120/230V AC, output: 24V DC/2.5A

7) All I/O ports adopt both plug-in and termination methods.

(2) Data visualization unit

Adopt Siemens KTP700 human-machine interface KTP700BASIC PN

1) 1 HMI basic color PN, basic panel, button and touch operation, 7" TFT display, 65536 colors, PROFINET interface;

2) 1 unmanaged industrial Ethernet switch suitable for 10/100MBIT/S;

3) All I/O ports adopt both plug-in and termination methods.

(3) Industrial remote IO unit

Select Siemens' new generation industrial distributed remote I/O system ET200SP

1) 1 standard mounting r*l, length: 483 mm

2) 1 Profinet Net network interface module

3) 1 digital input module 8 inputs 24VDC/0.5A

4) 1 digital output module 8 outputs 24VDC/0.5A

5) 2 RJ45 bus adapters

2 base units, type A0, 2 separate feed terminals (digital/analog) 24VDC/10A

6) All I/O ports adopt both plug-in and termination methods.

(4) External input/output interface unit

1 set of platforms that provide signal connections with sensors /actuators or original teaching equipment , as well as signal connections with optional desktop sorting devices and desktop water tower water levels.

1) 8 digital input quick connection ports

2) 8 digital output quick connection ports

3) 6 24VDC power supply quick connection ports

4) All I/O ports adopt two methods: plug-in and termination.

(5) Creatively build control objects

One set cont*ns multiple sensors/actuators, providing students with a practical platform from controlling a single object to building a simple control system. include:

1) 1 DC motor industrial grade lifter, voltage range: DC 20.4 - 28.8 V, maximum push rod stroke: 200mm, with internal safety limit

2) 1 inductive proximity switch, voltage range: DC 20.4 - 28.8 V, detection distance: 1.5~15mm

3) 1 reflective photoelectric switch, voltage range: DC 20.4 - 28.8 V, detection distance: >0.5m

4) 1 emergency stop switch, rotation reset, normally open/normally closed optional

5) 1 push button switch, self-resetting, normally open/normally closed optional

6) 2 indicator lights, voltage range: DC 20.4 - 28.8 V, color: one red/green

7) 1 intermediate relay, voltage range: DC 20.4 - 28.8 V

1 micro DC motor. Voltage range: DC 20.4 - 28.8 V

8) All I/O ports adopt both plug-in and termination methods.

(6) Logic programming control objects

1 set of signal simulation, including analog devices that provide real analog signals and switching signals, which can simulate the operating status of equipment in industrial sites. include:

1) 2 voltmeters to measure AQ output voltage.

2) 2 direct sliding resistors, providing 0~12V DC voltage signal.

3) 8-way switch and 8-way LED display.

Object cards used in supporting teaching include: traffic lights, stamping machines, running water lights, vending machines, robots , tower lights, washing machines, and automatic doors. They adopt a universal bottom box plus card design, with built-in LED lights, switches, and safety devices. Connecting posts, all I/O ports are open.

(7) Motion control objects

Provide a set of Siemens servo motors and Siemens servo drives that support multiple communication methods, are configured with an Ethernet port, and support position control, speed control, and torque control. One set of linear bearings, one set of screws, one set of polished rods, four button switches, and three sensors

(8) Frequency conversion control object

Provide a Siemens inverter G120C with a power of 0.37KW and a voltage of 380V. It supports 6 digital inputs, 4 outputs, two analog inputs and outputs, and a three-phase asynchronous motor with a power of 180W.

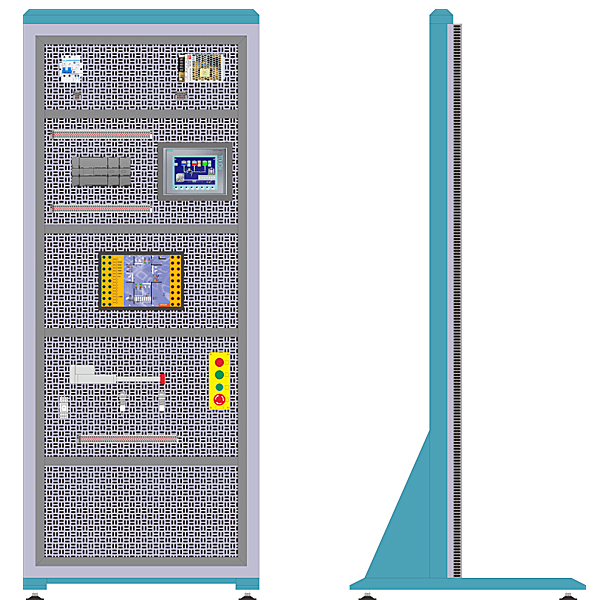

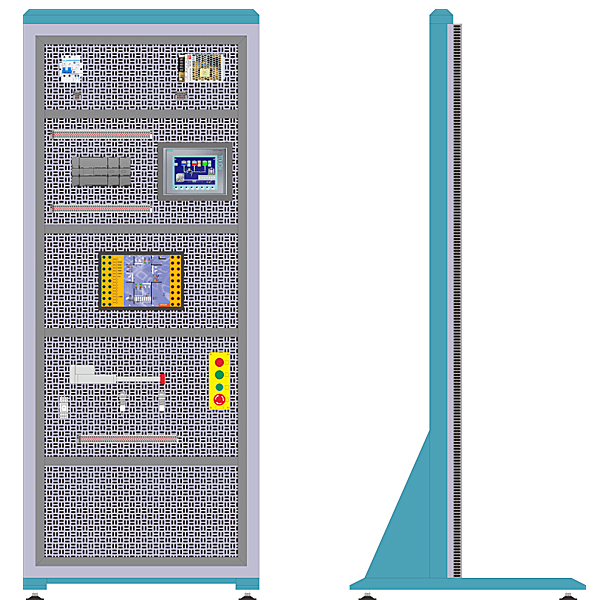

(9) Product platform size

1 set of mesh standard control panel (desktop): H2000*W800*D800

Matching computer desk, aluminum profile steel wood structure.

3. Practical tr*ning projects

(1) PLC positioning instruction practice

(2) PLC reset command practice

(3) PLC movement command practice

(4) PLC transmission instruction practice

(5) PLC edge command practice

(6) PLC trigger instruction practice

(7) PLC addition instruction practice

(8) PLC subtraction instruction practice

(9) PLC multiplication instruction practice

(10) PLC division instruction practice

(11) PLC counter instruction practice

(12) PLC timer instruction practice

(13) PLC AND or NOT instruction exercises

(14) Practical tr*ning on basic instructions of PLC

(15) PLC analog data processing tr*ning

(16) Traffic light PLC control tr*ning

(17) PLC control tr*ning for stamping machines

(18) PLC control tr*ning for running water lamps

(19) PLC control tr*ning for vending machines

(20) PLC control tr*ning of manipulator

(21) PLC control tr*ning of Tianta Light

(22) PLC control tr*ning of washing machine

(23) PLC control tr*ning for automatic doors

(24) PLC control of automatic lifter

(25) Basic screen editing tr*ning on touch screen

(26) Touch screen communication parameter setting tr*ning

(27) Practical tr*ning on downloading programs on the touch screen

(28) Touch screen traffic light control tr*ning

(29) Distributed communication control between PLC and remote I/O

(30) PLC and touch screen communication tr*ning

(31) Parameter settings of servo motor

(32) External terminal control of servo motor

(33) Position control of servo motor

(34) Servo motor analog control

(35) Servo motor communication control

(36) Frequency converter parameter setting

(37) Start and stop of the inverter panel

(38) Start and stop of the external terminal of the frequency converter

(39) Frequency converter analog control

(40) Frequency converter communication control

(41) Touch screen, PLC, inverter bus communication control

(42) Touch screen, PLC, servo motor bus communication control

Hot-selling product: Electrician tr*ning bench

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap