This equipment is designed in accordance with the "Pilot Work Plan for Teaching Reform of Integrated Work-Study Courses in Technical Colleges" of the Ministry of Human Resources and Social Security of the People's Republic of China. It determines course goals around typical work tasks (i.e. FMS), selects course content, and formulates professional teaching plans. According to the national vocational The relevant content in the standard organically combines the " electrical control technology" and "programmable programmer" in the combination of mechanical and electrical engineering through the tr*ning of work tasks, so as to realize the quantification of typical work tasks into multiple sub-tasks and implement them step by step. With the new concept of task-led, project-driven, and modular teaching, we follow the teaching rules and use advanced means of situational teaching to simplify complex knowledge points, clarify profound theoretical points, and be close to the actual corporate work content and processes. The practical tr*ning workshop and the enterprise, the practical tr*ning teachers and the enterprise employees, the practical tr*ning content and the work tasks are truly integrated into one, so as to achieve the purpose of integrated teaching with work and study.

The plc skills work island is a combination of practical tr*ning tasks for multiple PLC skills. It combines multiple technologies such as touch screens, frequency converters, sensor technologies, and pneumatic components. The table body of the PLC skills work island adopts a three-sided arc shape. It is suitable for three groups of six people to conduct teamwork tr*ning; the PLC skills work island *ms at ability cultivation and is designed with "programming and debugging of basic task models ", "installation and debugging of automated assembly sub-task systems", and "starting control of three-phase asynchronous motors" ", "Touch screen screen production and configuration", "Programming and debugging of material delivery and picking task models", "Programming and debugging of intelligent storage task models" and other typical tasks.

Each typical work task has its core content. In the basic task model, it is m*nly *med at basic programming tr*ning for PLC p*ring; in the automated assembly sub-task, task assembly and debugging can be carried out to tr*n students' hands-on ability; 3. The asynchronous motor task control complies with the basic tr*ning content for electricians and can also be controlled by PLC; the programming and debugging of material picking tasks deepens the comprehensive use of PLC, sensors, frequency converters and other components; the intelligent storage task model is based on Learn servo motors, stepper motors, and PLC analog quantities, and master servo and stepper principles and advanced application technologies of PLC; in short, this system covers the basic, intermediate, advanced, and partial technician tr*ning content for m*ntenance electricians , fully embodying the integration The importance of cultural skills is conducive to cultivating students' pioneering and innovative thinking mode.

2. Technical parameters:

Working power supply: three-phase four-wire AC380V±5% 50Hz

Safety protection: Leakage protection (action current ≤30mA), overcurrent protection, fuse protection

Rated power: 2KW

Ambient temperature: -10℃~40℃

Relative humidity: ≤85%

Workbench size: 2500mm (diameter) × 775mm (height);

Virtual multimeter parameters: AC voltage range points: 10, 50, 250, 1000; DC voltage range points: 0.25, 1, 2.5, 10, 50, 250, 1000; Ohm range points: x1, x10,,100 ,,1000,,1K,x10K,x100K; Ammeter range: 50μa, 0.5, 5, 50, 500; BATT: 1.2-3.6V, RL=12Ω; BUZZ: R×3; Infrared emission detection function: vertical angle ± 15° distance 1-30cm; triode measuring hole

3. Product structure:

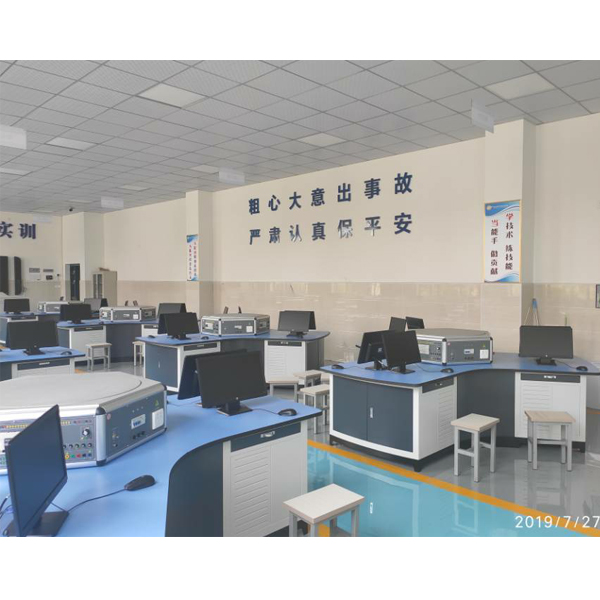

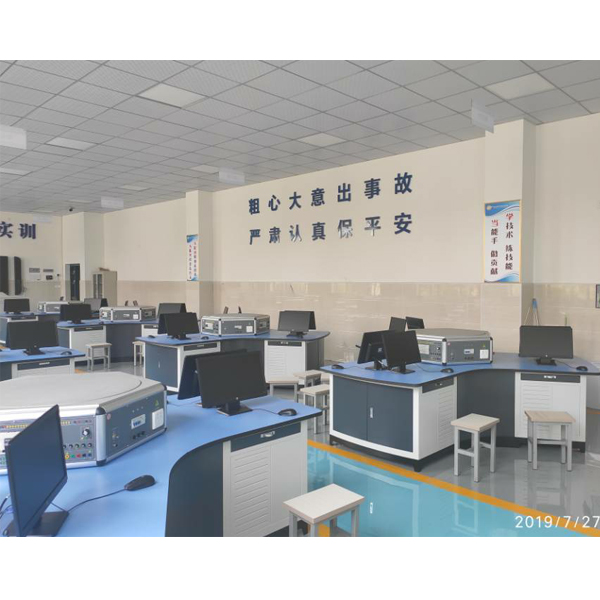

The skill work island consists of a three-sided arc workbench, a hexagonal tr*ning control screen and typical work tasks. It can accommodate 6 students to operate on the equipment at the same time.

Three-sided curved worktable: The table body is made of 1.5mm thick high-quality Anshan steel boxed steel plate as the frame. It is machined and formed, and the outer surface is sprayed with colorful epoxy polyplastic. The whole machine is both strong and durable, and beautiful and elegant. The workbench is designed with three arc-shaped workstations on three sides, and each workstation is equipped with a storage cabinet where a computer host can be placed. The desktop has a three-sided arc structure, made of 25mm thick solid core physical and chemical board, with a fireproof board on the outer surface. It is milled and formed by CNC equipment, and the table edges are rounded. The diameter of the workbench is 2500mm, and the height is designed according to ergonomic requirements, which is 755mm.

1. Hexagonal tr*ning control screen: The tr*ning control screen adopts a hexagonal structure. The frame is made of 30 R semi-circular aluminum profiles and is assembled with special connectors. The top and bottom surfaces are connected with §1.2mm thick high-quality steel plates. The arc-shaped working surfaces on three sides are equipped with tr*ning power supply, *r source and PLC host control system, which are independent of each other and do not interfere with each other. The control panel buttons are thin-film light-touch designs with leakage protection and short-circuit protection functions. The top surface of the power control screen is wrapped with a 10mm thick aluminum frame and has a built-in multi-angle public operating platform with a diameter of 850mm. The public operating platform can rotate 360° and can be positioned at 120°. The top plate of the platform is processed and formed from a 10mm thick aluminum plate. Typical work tasks that can carry a load of about 60Kg. Three-purpose meter simulation software: This software is in apk format and can be used on PC or mobile terminals. The functions of this software are: measurement of resistance, measurement of AC voltage (measuring transformer, if the transformer is burned out, it is useful for measuring When the meter is running, black smoke will appear and you can reset the multimeter), determine the polarity of the transistor, measure the DC voltage (the light will turn on when the ammeter is turned on), measure the DC current, and judge the quality of the capacitor. This software can drag the red and black pen tips at will. When the two pen tips are dragged and positioned on the object to be measured, a red circle will be displayed. If the positioning is not accurate, no red circle will be displayed, and when incorrect operations are performed (such as the wrong range selected, If the measured data is wrong, etc.), the meter pointer will be unresponsive, prompting errors and re-measurement, etc. This multimeter can select AC voltage range, DC voltage range, resistance range, current range, resistance adjustment to 0, and can enlarge the display data. Clearly view the measured data size. Students can learn the correct use of multimeters through this software.

2. Typical task model of intelligent storage:

The base plate of the model is processed and oxidized from a 10mm thick aluminum plate. The model is composed of a stacker, a three-dimensional warehouse, a handling manipulator, a weighing and feeding mechanism, sensors, cylinders, etc.; all mechanisms are made of 1.2mm high-quality steel plates, spray-p*nted or machine-machined from aluminum. Made of oxidation, strong and durable. The stacker for this task has stepper and servo control and is responsible for the entry and exit of materials; the manipulator is responsible for transporting materials before and after feeding; the weighing and feeding mechanism weighs and feeds materials. At the same time, in order to facilitate teaching, a fully open task interface box was developed. The box body is made of 1.2mm high-quality steel plate and spray-p*nted. The panel is made of aluminum plate, spray-etched and punched. It is connected to the intelligent storage task model through a parallel port cable to stack the terminals. The open model interface is convenient for practical tr*ning and teaching.

3. Three-phase asynchronous motor task model:

The task box is made of 1.2mm high-quality steel plate and spray-p*nted. The panel is punched and punched from aluminum plate, and the surface is made of film. It has built-in AC contactor, intermediate relay, time relay, circuit breaker, button, etc., and connects to the external teaching *d motor through stacked terminals. Connection to meet various teaching purposes of the motor, convenient and flexible. Teacher teaching design system: This system is in apk format and can be used on PC or mobile. This system can manually set faults or automatically set faults. This system can manually set faults by selecting the green box in the circuit diagram. points (up to 39 fault points can be set), or the system can automatically set one random fault point, two random fault points, three random fault points, four fault points randomly, and five fault points randomly. Settings, this system has toolbox, component library, magnifying glass, circuit diagram and other functions. You can select a multimeter for testing through the toolbox, select appropriate components through the component library, and clearly understand each component and circuit through the magnifying glass. This system allows students to understand the working principle and circuit structure of the motor star-delta start control circuit through the setting of faults in the motor star-delta start control circuit and various investigations.

4. Automated assembly and adjustment task model:

This task consists of a pneumatic manipulator, a sorting mechanism, a loading mechanism, an installation mesh plate, an electrical interface board, a solenoid valve group, etc. The installation mesh plate is made of 1.2mm high-quality st*nless steel plates, and the mechanical components are machined from aluminum. It is made of oxidation, and all the mechanisms are provided in parts. According to the teaching requirements, students must assemble, wire and debug by themselves through the interface board.

5. Touch screen task model:

The task box is made of 1.2mm high-quality steel plate and spray-p*nted. The panel is punched and punched from aluminum plate, and the surface is made of film. The touch screen is installed with a surface snap-in, which leads to the touch screen communication interface and power supply, which is convenient for tr*ning and easy to protect and transport the touch screen. .

6. Basic task model:

The task box is made of 1.2mm high-quality steel plate and spray-p*nted. The panel is punched and punched from aluminum plate, and the surface is made of film. It is equipped with a DC motor, a 7-segment digital tube, a lantern set, a relay set, a button set, a potentiometer, etc. It can Meet the learning and application of basic task instructions for PLC teaching.

7. Microcontroller and PLC programmable design and control virtual simulation software:

This software is developed based on unity3d and has built-in experimental steps, experimental instructions, circuit diagrams, component lists, connection lines, power on, circuit diagrams, scene reset, return and other buttons. After the connections and codes are correct, you can start/stop, The forward movement and reverse movement buttons operate the 3D machine tool model to move. In the connected line state, the 3D machine tool model can be enlarged/reduced and translated.

1. Relay control: Read the experiment instructions and enter the experiment. By reading the circuit diagram, select the relays, thermal relays, switches and other components in the component list and drag and drop them into the electrical cabinet. The limiters are placed in the three-dimensional On the machine tool model, you can choose to cover it, and some component names can be renamed. Then click the Connect Line button to connect terminals to terminals. After successfully connecting the machine tool circuit, choose to turn on the power and proceed. If the component or line An error box will pop up if there is a connection error, and the scene can be reset at any time.

2. PLC control: The experiment is the same as relay control, with the addition of PLC control function. After the connection is completed, enter the program writing interface through the PLC coding button, and write two programs, forward and reverse, with a total of 12 ladder diagram symbols. The writing is completed. Finally, select Submit for program verification. After the verification is successful, turn on the power for operation. Error boxes will pop up for component, line connection, and code errors, and the scene can be reset at any time.

3. Single-chip microcomputer control: The experiment is the same as relay control, with the addition of single-chip microcomputer control function. After the connection is completed, enter the programming interface through the C coding button, enter the correct C language code, and after successful submission and verification, turn on the power for operation, components, lines If there are connection or code errors, an error box will pop up, and the scene can be reset at any time.

4. Configuration list of each skill work island task model

|

serial number |

name |

Specification |

quantity |

Remark |

|

1 |

Intelligent storage task model |

1 |

||

|

2 |

Automated assembly and adjustment task model |

3 |

||

|

3 |

Touch screen task model |

Kunlun Tongt* 7-inch color |

3 |

|

|

4 |

Basic task model |

3 |

||

|

5 |

Three-phase asynchronous motor task model |

380V/180W |

3 |

|

|

6 |

Frequency converter task model |

D720 0.4W |

3 |

|

|

7 |

PLC task model |

FX3U-48MR |

3 |

|

|

8 |

*r pump |

1 |

||

|

9 |

Material sorting model |

3 |

||

|

10 |

computer |

3 |

5. Typical work tasks of PLC skills work island

A. M*ntenance electrician technician learning tasks

1. Awareness of touch screens

2. Touch screen screen production and configuration

3. PLC analog module control weighing unit program design

4. Positioning control of PLC pulse control stepper system

5. Positioning control of PLC pulse control servo system

6. Use PLC, touch screen, stepper system, and servo system to control the three-dimensional warehouse

B. Learning tasks for senior m*ntenance electricians

1. Assembly of pneumatic manipulator

2. Assembly of sorting mechanism and feeding mechanism

3. Use PLC step instructions to control the robot hand

4. PLC controls material sorting through sensors

5. PLC controls the simple manipulator through set and reset instructions

6. Tr*ning on PLC controlled automated assembly and adjustment tasks

7. PLC uses basic instructions to control the answering machine

8. PLC uses step instructions to control the answering machine

9. Multi-stage speed control conveyor belt with frequency converter

10. PLC controlled frequency converter driven conveyor belt

11. Comprehensive applications such as PLC controlled frequency converters, simple manipulators, and pneumatic devices

C. Learning tasks for intermediate m*ntenance electricians

1. Understand PLC

2. Learn to use PLC programming software

3. Use PLC to control the one-way operation of DC motor

4. Use PLC to control forward and reverse rotation of DC motor

5. Y-△ step-down starting control of three-phase asynchronous motor

6. Use PLC to control the reciprocating operation of the three-phase asynchronous motor

7. Use counters and timers to control traffic lights

8. Use step sequence control method to control traffic lights

9. Simple lantern control

10. Light flashing pattern control

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap