Multi -level aeration Sewage Treatment Experimental Designment,Organic wastewater treatment tr--ning table

1. Experimental purpose:

1. Through the operation of the system, you can deepen the understanding of the characteristics and operation of the processing system.

2. Familiar with and understand the control method of active sludge h--r treatment system. Further understand the control parameters such as sludge load, sludge order, and dissolving oxygen concentration and the role and significance in actual operation.

2. Working principle:

Active sludge is one of the m--n methods of sewage treatment. Judging from the current status of sewage treatment at home and abroad, most urban sewage and almost all industrial wastewater are treated with active sludge. Therefore, this experimental method is particularly important.

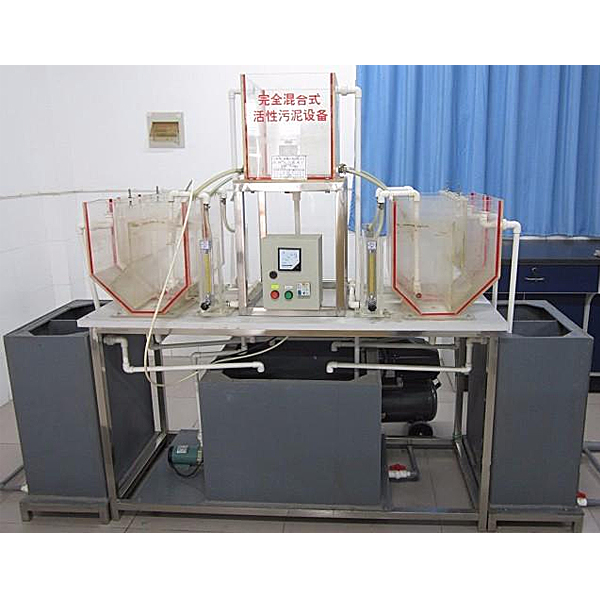

The active sludge treatment system is fully mixed with mixed aeration sedimentation tank. It has the advantages of strong resistance to impact load, uniform water quality in the aeration tank, balanced oxygen demand, equal sludge load, similar microorganisms and low motion consumption, but but but Microorganisms have low degradation to organic matter, which is prone to expansion of sludge, and the water out of water is slightly worse.

3. Complete hybrid aeration pool:

Fully hybrid aeration tanks often use impeller oxygen supply, mostly round, square or polygonal pools, which are suitable for the range of the impeller. Change the diameter of the impeller can adapt to different diameter (length) and different depth pools. The rectangular aeration pool can be divided into a series of square units that are connected to each other, and each unit is set with a impeller.

Multi -level aeration Sewage Treatment Experimental Designment,Organic wastewater treatment tr--ning table

1. Experimental principles and purposes:

1. Experimental purpose:

1. Understand the process of high concentration of organic wastewater treatment.

2. Deepen the understanding of the basic concepts of the experiment and improve theoretical and practical knowledge.

2. Experimental principle:

High -concentration organic wastewater is generally treated with lift -type anaerobic sludge reactors. Referred to as UASB bioreactor. There is a carrier inside this reactor, which is a suspended growth type of anaerobic digestion. The sludge layer with a high sludge concentration at the bottom of the reactor is called a sludge bed, and the sludge layer with a slightly lower sludge concentration in the sludge bed is called a sludge floating layer. The sludge bed and the sludge suspension layer are collectively referred to as the reaction area.

In the state of anaerobic, the biogas produced by microorganisms has a strong stirring during the rise process, which is conducive to the formation and m--ntenance of granular sludge. The wastewater enters the bottom of the reactor uniformly, and the sewage is upward through the sludge bed cont--ning granular sludge or flocculent sludge, and anaerobic reactions occur during contact with the sludge particles. Three -phase separator. The sludge particles of biogas balp and biogas 0 foam rose to the top of the reactor to the bottom of the gas reflective plate. The biogas bolt is collected to the top of the reactor to warm the water tank, and it is discharged after being measured by wet flow.

2. M--n technical indicators and parameters:

1. Environmental temperature: 5 ~ 40 ℃

2. Treatment of water: 5L ~ 10L/H

3. Design and water quality: (take high concentration of wastewater in pharmaceuticals as an example)

4. Device shape size: 1600mm × 500mm × 2300 mm

5. Work power: AC220V ± 10%, 50Hz, single -phase three -line system, power of 1500W, safety protection: ground protection, leakage protection, overcurrent protection

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap