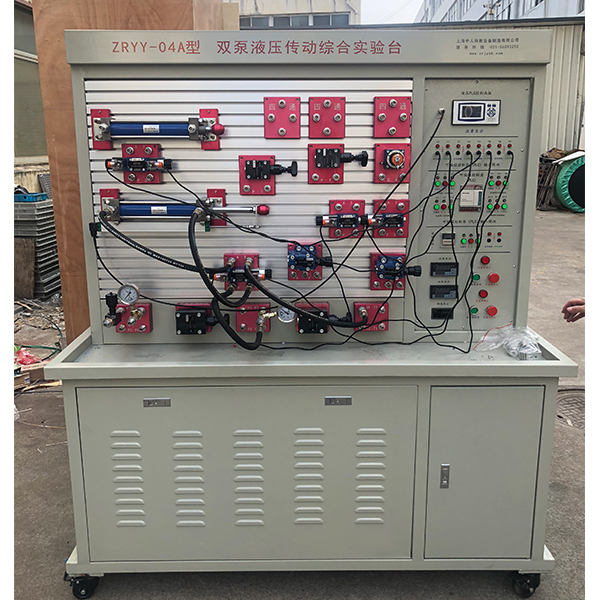

Double pump group hydraulic tr--ning device,Intelligent manufacturing digital twin virtual simulation tr--ning device

The industrial hydraulic comprehensive experimental desk is a experimental designed based on the characteristics of modern teaching and the required for the teaching outline of the hydraulic transmission course. It adopts advanced Loser's hydraulic elements and unique modularization, forming a convenient system combination of insertion to meet the experimental teaching requirements of students from colleges, secondary majors, and vocational technical schools. Handling, design and comprehensive application ability improved and strengthened the purpose of students' innovative design ability.

1. M--n features:

1. The system uses standard industrial hydraulic components, which is safe and reliable and close to industrialization.

2. Fast and reliable connection methods, special sealing interfaces, ensure that the experimental assembly is convenient and fast, disassembled without oil leakage, and clean.

3. Accurate measuring instrument, convenient measurement method, simple use, accurate and reliable measurement.

4. Use compilation controller (PLC) to communicate with microcomputer to achieve electrical automation control, online programming monitoring and fault detection.

① Basic circuit experiment of hydraulic transmission:

1. Pressure circuit of overflow valve

2. The decompression circuit of the pressure decompression valve

3. The load load load on the directional valve

4. The load -loading circuit of the pilot overflow valve

5. Slotting valve inlet oil inlet Small speed adjustment circuit

6. Slotting valve return oil -reinforcement speed adjustment circuit

Double pump group hydraulic tr--ning device,Intelligent manufacturing digital twin virtual simulation tr--ning device

1. Software introduction

The software is a three -dimensional intelligent simulation software, based on a large amount of element model, and quickly builds simulation projects in a drag and drag method. The virtual equipment and real equipment have the same characteristics. Drive virtual devices such as PLC programs, robotic programs, machine tool CNC programs, etc., and complete the debugging and verification of the entire project in the virtual scene. Through mechanical physics engines, achieve actual operating effects.

Software integrates the functions of PLC simulation, robot simulation, and smart factory simulation. Provide users with independent modeling and independent layout functions, and open the underlying interface to support users' secondary development. It is a comprehensive design simulation verification platform for industrial 4.0 automation, and provides rich teaching resources.

In the industrial field, the entire system can be fully analyzed in the primary concept stage of production line design, including virtual debugging, beat verification, risk assessment, improvement of schemes, and reducing project technology risks. In the field of education, through the virtualization of objects, it solves the problem of high engineering tr--ning costs and few scenes. Can be used for college students competitions, open experiments, graduation design, etc.

Recommended hardware system configuration

In order to ensure the smooth use of the system, the configuration requirements of the computer system:

Operating system: Windows 7 SP1 and above versions

System type: 64 -bit operating system

Processor (CPU): ≥2.5GHz (if VR glasses are used, ≥3.2GHz)

Memory: ≥8GB

Hard disk: ≥5GB

Variety: ≥1GB (using VR glasses, video memory ≥6GB, such as GTX1070)

.NET framework version: V4.6.2 and above versions

Software feature function

1. Industry 4.0 system virtual integration

Including independent development models, automatic layout, electrical connection design, programming, virtual debugging, the entire system integration process.

2. Multi -brand PLC virtual reality combination simulation

Support semi -solid simulation of various m--nstream brands PLC (combination of virtual reality) and full virtual simulation.

3. Multi -brand robot virtual reality combination simulation

Support semi -solid simulation (combination of reality) and full virtual simulation of various m--nstream brand industrial robots.

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap