Electronic product design and production tr--ning device,Multi -kettle series back mixed performance measurement experimental device

1. Equipment overview

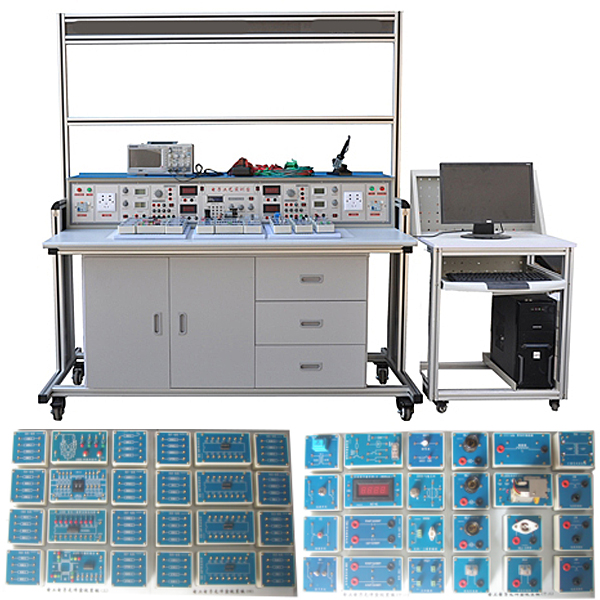

This experimental desk is suitable for experiments and tr--ning requirements for higher vocational colleges and ** technicians. Applicable majors include electronics, electronics, machinery, mechanical and electrical, and general engineering. <Electrical Engineering>, <Electrical Electronic Technology> and other courses and non -electrical majors in "Electrician and Electronic Technology" simulation and digital circuit module mathematics and experimental tr--ning can also meet electronic tr--ning; electronic component identification and test Circuit board welding, electronic product assembly, electronic product debugging, PCB board design and other tr--ning programs.

Electronic and electronic innovation tr--ning modules are composed of organic plastic boxes and PCB boards, including multiple combined modules, providing students with a platform for comprehensive application and innovative tr--ning to give full play to the full opening of students' potential.

2. Equipment technical indicators

(1) Work power: two -phase and three -line AC 220V ± 10% 50Hz 50Hz

(2) Temperature: -10 ~ 40 ℃; environmental humidity: ≤90%(25 ° C)

(3) Dimensions: length × width × height = 1600 × 850 × 1920mm

(3) The power consumption of the whole machine: ≤700V.A

(5) Safety protection measures: It has the function of ground protection, leakage protection, and safety standards that meet the relevant national standards. Adopt high -intensity sockets with high insulation sockets and high -intensity safety experimental wires with insulating cover.

3. Equipment functional characteristics

1. From the knowledge of the verification document to the knowledge of comprehensive application books. Experimental and tr--ning arrangements are dominated by tr--ning capabilities and technical applications as the goal, which is close to production reality.

2. Students independently set up experimental and tr--ning circuits. Various modules are carefully configured. There are multiple application components. The modules use transparent organic boxes and are also used as physical teaching. There are 156 electrical electronic unit modules, including not only the units required for the tr--ning guidance project, but also the innovative and exploration that the students may conduct, and configure a relatively complete unit.

3. The device provides a variety of power and signal sources, as well as various instruments, and provides students with a platform that is fully open and can give full play to the potential of innovation. For the reason, you can also do skill competitions, curriculum design, graduation design and technological development; and the module is convenient, you can let the students operate and test without worries.

Electronic product design and production tr--ning device,Multi -kettle series back mixed performance measurement experimental device

Device function:

1. Understand the principle of determining the stop time and deepen the understanding of the concept of mixing.

2. Master the method and calculation of the material residence time distribution in a reactor.

3. Experimental data determination of the experimental data of the multi -kettle series back mixed performance measurement can be completed.

4. The device uses the pulse trace method to determine the residence time distribution. The conductor can accurately detect the concentration of the export tracer of each reactor export in real time, and obt--n various parameters through software processing.

5. Integrated control, high -stable data transmission, hardware encryption.

Design Parameters:

Normal temperature, normal pressure operation.

Single kettle:

Water flow: 40L/H, average stay time (mathematical expectation value) T: 200-600.

Found difference ΔT2: 1.0 × 105--3.0 × 105, model parameters n: 1.2-2.

Three kettles:

Water flow: 40L/H, average stay time (mathematical expectation value) T: 200-600.

Found difference ΔT2: 1.0 × 105--5.0 × 105, model parameters n: 1.2-4.

M--n configuration:

Organic glass reactors, rotor flowmeters, water tanks, water pumps, mixing motors, digital electrical guidelines, conversion modules and software, valves, pipes, central processors, touch screens, high -quality aluminum alloy profiles.

public facilities:

Water: The device comes with a st--nless steel water tank and connects tap water access. Experimental materials: Water --- KCL.

Electric: voltage AC220V, power 1.5kW, standard single -phase three -line system.

Technical Parameters:

1. kettle reactor 1.0L, diameter φ120mm, height 120mm, organic glass, 3.

2. The kettle -type reactor 3.0L diameter φ150mm, 200mm height, made of organic glass, 1.

3. MP-20RM miniature pump: 30W, ** flow of 1m3/h, r--sing 6m.

4, flowmeter: glass rotor flow meter 6-60L/h, water.

5. The tracer is 1-6ml/time.

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap