Adsorption principle tr--ning device,Combined Mechanical and Electrical Comprehensive Experimental Device

1. Experimental purpose:

The activated carbon treatment process is an organic pollutant that uses adsorption to remove odor, cert--n ions, and difficulty in biodegradation. During the adsorption process, activated carbon plays a m--n role. At the same time, the solubility of the adsorption substance in the solvent also directly affects the speed of adsorption. In addition, the level of pH, changes in temperature, and decentralization of adsorption substances have a cert--n impact on adsorption speed.

This experiment adopts the method of intermittent and continuous adsorption of activated carbon, which determines the adsorption capacity of some impurities cont--ned in water through this experiment. Hope to achieve the following goals:

1. Master the basic operation process of adsorption experiments;

2. Deepen the basic principles of adsorption;

3. Master the physical significance and functions of adsorbing the temperature line;

4. Master the data processing method of activated carbon adsorption experiments;

5. Understand the adsorption performance of different activated carbon and its choice method.

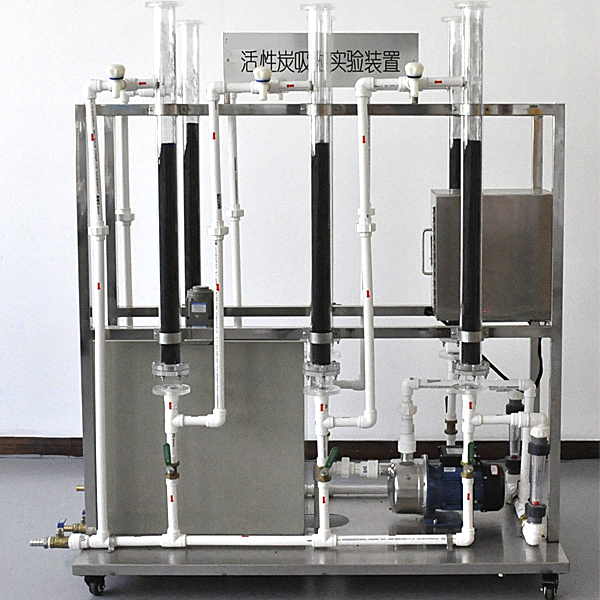

2. M--n technical indicators and parameters:

1. Environmental temperature: 5 ℃ ~ 40 ℃

2. Active carbon suction column: φ100mm × 2000mm (group 2)

3. Device shape size: 1000mm × 600mm × 2200mm

4. Work power: AC220V ± 10%, 50Hz, single -phase three -line system, 200W power, safety protection: have ground protection, leakage protection, overcurrent protection.

3. M--n configuration:

1. 2 active carbon suction columns (parallel): transparent organic glass material, 6mm wall thickness, φ100mm × 2000mm; water inlet pipes, dr--nage pipes, backwashing into the water pipe, rinse water pipe, empty exhaust pipe, sampling port, etc. Items

2. 1 raw water tank (white 10mm thick PP board), and the empty valve is installed on the bottom plate for convenience to clean the water;

3. Mix 1 set of original water tank motors and 1 set of 304 st--nless steel mixing paddles; (power 15W, speed 120rpm);

4. 1 setting pump for anticorrosive magnetic pumps, flow: 27 ~ 32 (L/min), r--sing: 3.1 ~ 4.3 (m);

5. Two water flow flowmeters and backwashing flowmeters (10-100L/h);

6, 10 copper sampling ports; specifications ø10mm.

Adsorption principle tr--ning device,Combined Mechanical and Electrical Comprehensive Experimental Device

1. Product overview

This device is a typical mechanical and electrical integration product, which is developed for vocational colleges and vocational education and tr--ning institutions. It is suitable for teaching and tr--ning in related majors such as mechanical and electrical integration and automation. This device adopts a profile structure, which is installed with an AC servo motor and driving unit, a step motor and a driver unit, a DC brushless motor and a driver unit, AC motor and frequency conversion speed regulating unit, touch screen unit, PLC and A/D/A Units, sensors and rotators, belt conveying units, rolling beads, and worm sn--l units. Using industrial components, all sensors, actuators, and controller interfaces are open. The tr--ning content includes: PLC (digital and simulation) technology, sensor and rotary encoder technology, DC brushless motor characteristics research, step motor characteristics research, research, and step -by -motor characteristics, and research, step motor characteristics research, research, research, step motor characteristics research, research, research, step motor characteristics, research, research, step motor characteristics, and research, and research on step motor characteristics. Exchange servo motor characteristics research, special motor control technology, touch screen technology, location and speed control technology, mechanical transmission (belt transmission, drill ricibility and worm worm -driven transmission) technology, configuration software monitoring technology, etc. The plane modular structure, the wiring of all control motors is open, the installation size is completely the same, the motor can be switched, and the control level is consistent.

2. Product characteristics

1. The practical tr--ning device organically integrates mechanical, electrical, sensors, AC motor variable frequency adjustment, DC brushless motor control, step motor driving control, servo motor -driven control, and task -driven project teaching.

2. The overall structure is open and disassembled, and has obvious hand -disassembly tr--ning functions. It can be disassembled to each component and each small screw, which can serve project tr--ning teaching well; can be based on different differential; can be dependent on different according to different. The task replacement combination module has a strong reorganization, which makes the module required for convenient selection during teaching or competition, which is very suitable for the majority of vocational colleges to automate the skills tr--ning needs.

3. For teaching, planning and teaching activities with a working process -oriented and combined model of engineering can complete the skill tr--ning tasks in a variety of industrial field environments.

4. This tr--ning assessment device PLC module I/O terminal, inverter wiring terminal, and common module wiring terminals are used in a safe socket and connect to the circuit with a wire with a safe plug; each instruction switch, photoelectric switch, sensor, and The circuit of the indicator element is connected through the terminal row. The combination of the plug -in connection circuit and the terminal row connection circuit not only ensure the tr--ning, formation and consolidation of the basic skills of students, but also to ensure the rapid, safe and reliable circuit connection.

3. Technical performance

1. Enter power supply: three -phase and four lines (or three -phase and five lines) ~ 380V ± 10% 50Hz

2. Working environment: temperature -10 ℃ ~+40 ℃ relative humidity ≤ 85%(25 ℃) Altitude <4000m

3. Device capacity: ≤1.0kva

4. Structural size: 1200mm × 800mm × 840mm

5. Safety protection: have leakage protection, safely meet national standards

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap