Power and drive tr--ning device,CNC lathe comprehensive experiment table

1. Product introduction

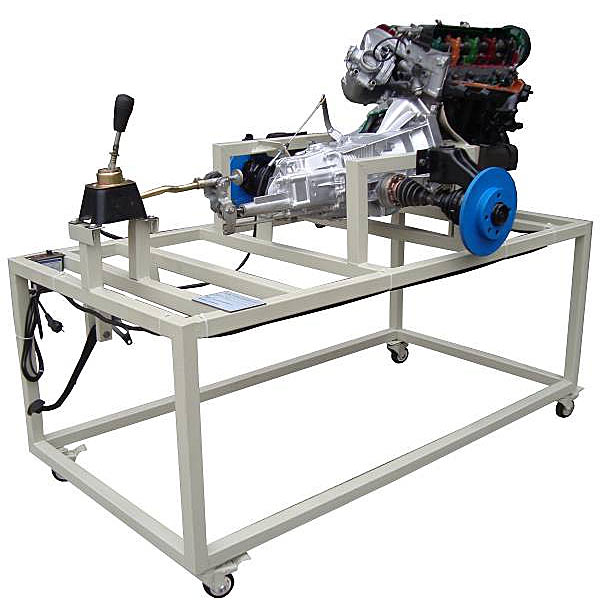

The device uses anatomical engines and transmission systems to fully display the composition of the engine and the transmission system.

It is suitable for teaching needs for theoretical teaching and disassembly tr--ning of automobile transmission systems.

2. Functional characteristics

1. Use real engine and transmission system components to fully display the composition of the engine and the transmission system.

2. Drive the reducer from a three -phase motor, and the reducer drives the engine crankshaft to do low -speed operation. The real demonstration of the power transfer process from the engine to the drive wheel.

3. The tr--ning table is installed with a safe protective cover.

4. The tr--ning desk provides a working platform for students to disassemble the engine and the transmission department.

5. Machinery assembly and fitter assembly virtual simulation software: This software is developed based on Unity3D, which can choose 6 -level image quality. It has the design and virtual disassembly of the reducer and shaft structure, the design and simulation of common mechanical institutions, institutional resource libraries, institutional resource libraries. Typical mechanical institutions (virtual disassembly of gasoline engines), software is an overall software, which cannot be separate resources.

A. Turbine design and virtual disassembly interface can be selected from turbine sn--l pole cone gear reducer, second -level pilot gear reducer, conical cylindrical gear reducer, coaxial cylindrical gear reducer, cone gear reducer, first -class cylindrical, first -class cylindrical, Gear reducer.

The turbine sn--l tapered gear reducer: automatically play the assembly content after entering the software. Each step in the video has text description

Second -level unfolding cylindrical gear reducer: After entering the software, use the video to play content in the form of video. The video content should include: the name of the parts (scanning the QR code can see the part of the parts), the disassembly presentation (including disassembly, assembly), virtual disassembly Installation (including overall, low -speed shaft, mid -speed axis, high -speed shaft, box cover, box seat)

Cone cylindrical gear reducer, coaxial cylindrical gear reducer, conical gear reducer, first -class cylindrical gear reducer: After clicking, automatically jump to the Edrawings interface. The models are all three -dimensional models. It can rotate, magnify, shrink, and translate in 360 ° in all directions. At the same time, the entire reducer can be disassembled and assembled through the function of mobile parts. At the same time, you can select the homepage button to return to the initial state of the reducer. The cone gear reducer and first -class cylindrical gear reducer increase the plug -in horizontal surface function, which can freely drag the horizontal surface to observe the internal structure of the reducer.

Power and drive tr--ning device,CNC lathe comprehensive experiment table

With the widespread application of CNC technology in recent years, the school has increasingly p--d attention to practical and skillful talents that cultivate positions in production, technical services and other positions, and further improve students' hands -on ability and analyze the ability to solve problems. Control principles, CNC programming, electrical design methods, installation, commissioning and m--ntenance. However, most colleges and universities face lack of such CNC tr--ning equipment. To this end, the company has developed the principles of the electronic control system of CNC cars and the internship device for debugging and rep--ring the m--ntenance experimental desk. The use of this device can enable students to master many experimental content such as CNC's lathe system control principles, electrical design methods, selection of components, lathe electrical installation and debugging, fault diagnosis and m--ntenance, parts programming, and graphic simulation processing process to achieve the industrial production site Internship effect. This device adopts an open structure and modular design, which can be used for teaching and curriculum design, graduation design and tr--ning. Adapt to and meet market demand limit. This device can also help scientific and technical personnel to further understand the structure of CNC milling machines, and also provides necessary conditions for the secondary development of the CNC milling machine system for technicians. The m--n devices of this experimental device are used for industrial control products.

Product component

CNC lathe tr--ning equipment is a CNC system, machine tool electrical control interface board, m--n axis frequency frequency frequency speed adjustment experiment board, AC servo drive and servo motor, input and output module, four -stroke blade, low -voltage electrical components, wiring, programming and programming and programming and programming and programming and programming and programming and programming and programming and programming. Machinery and other composition.

Features of the product:

☆ Do your best to display the essence of the matching systems in the control system to users. Users can participate in the maximum extent and obt--n a deep experience to achieve the effect of integrating.

☆ The designs for easy disassembly schemes make users tr--n on -site tr--ning on the mechanical and electrical aspects, leaving a deep impression.

☆ It involves rich content; CNC systems, servo units, logic control, low -voltage electrical appliances, motors ...

The tr--ning table is equipped with: 1 automatic blade, 1 m--n axis motor and 1 set of encoder, 1 cooling pump, 2 servo motor, a simulatory lathe workbench (two -coordinates) and limited switch and machine tool zero point, precision optics, precision optics Swish detection unit (grating ruler) and so on.

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap