Performance test description of centrifugal pump performance,Comprehensive experimental description of hydraulic and pneumatic transmission

Feature

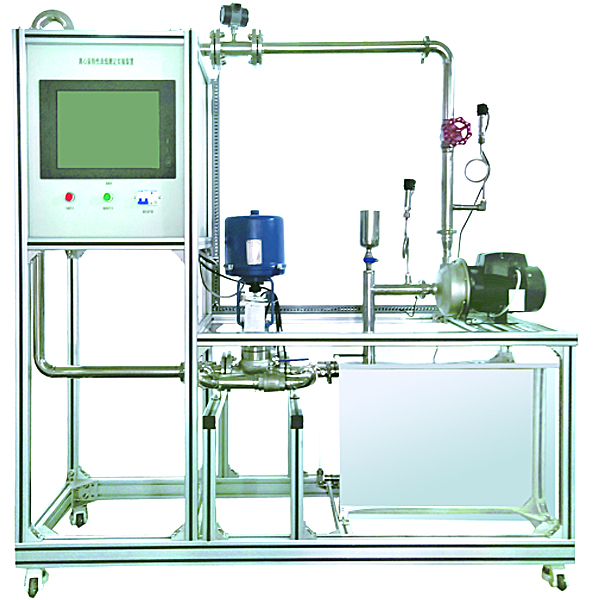

1. The entire device is beautiful and generous, with a reasonable structure design, and has a strong engineering atmosphere, which can fully reflect the concept of modern laboratories;

2. The equipment layout is reasonable, beautiful, the structure is clear, and the overall sense is strong. It can reflect the concept of the m--n experimental equipment in the laboratory.

3. The equipment is a self -propelled frame structure, and the feet are installed to facilitate the disassembly m--ntenance and handling of the system.

4. The flow measurement uses the turbine turbine meter. The data processor has a strong compensation function for the linear coefficient of the turbine flowmeter, and the flow data directly displays the flow data.

5. The centrifugal pump is placed above the water tank. The centrifugal pipe is installed with a bottom valve. At the same time, a centrifugal pump is installed to start the exhaust device to avoid the centrifuge of the centrifugal pump leaf wheel and the cavity soak in the water for a long time, which greatly extend the life of the equipment.

6. The entire system adopts a standard industrial instrument control system, which can perform chemical principles experiments. It is also a good platform for process automation and chemical testing instrument experiments.

7. Device design can be observed at 360 degrees to achieve comprehensive teaching and experiments.

Device function

1. Let students fully understand the structure and characteristics of the centrifugal pump, and be familiar with the working methods and operation processes of centrifugal pumps.

2. Familiar with various pipes and valves that form the pipelines, understand the instrument and sensor detection equipment on the spot, such as temperature, pressure, electrical power, traffic, etc., and master the measurement principles and usage methods of turbine turbines.

3. Measure the pump characteristic curve between the pumps (H), axis power (n), and efficiency (η) and the flow of the pump (q) under constant speed conditions.

4. Determine the characteristic curve of the pipeline under the opening degree of the flow regulating valve.

5. Change the pump characteristic curve between the pumps of the centrifugal pump speed measurement pump, axis power (n), and the traffic (Q) of the efficiency (η) and the pump (Q).

6. Master the method of multiple regression and regression (H-Q, η-Q, N-Q) relationship curve.

7. Use a computer to collect the experimental data, while controlling liquid flow.

8. Integrated control of full touch, high stability data transmission, hardware encryption.

Performance test description of centrifugal pump performance,Comprehensive experimental description of hydraulic and pneumatic transmission

The industrial hydraulic and pneumatic comprehensive experimental desk is a experimental designed based on the characteristics of modern teaching and the latest hydraulic transmission course teaching outline. It adopts advanced Hydraulic elements and unique modularization of Luxile technology, constitutes a convenient system combination of insertion to meet the experimental teaching requirements of students from colleges, secondary professional schools, and vocational technical schools. Handling, design and comprehensive application ability improved and strengthened the purpose of students' innovative design ability.

1. M--n features:

1. The system uses standard industrial hydraulic components, which is safe and reliable and close to industrialization.

2. Fast and reliable connection methods, special sealing interfaces, ensure that the experimental assembly is convenient and fast, disassembled without oil leakage, and clean.

3. Accurate measuring instrument, convenient measurement method, simple use, accurate and reliable measurement.

4. Use compilation controller (PLC) to communicate with microcomputer to achieve electrical automation control, online programming monitoring and fault detection.

① The performance test of commonly used hydraulic elements

1. Feature test of hydraulic pump

2. Feature test of the flow valve (static test)

3. The characteristic test of the throwing speed valve

② Basic circuit experiment of hydraulic transmission:

1) Pressure circuit of overflow valve

2) Simple pressure adjustment circuit

3) The flow valve buffer circuit

4) Two stress circuits

5) Two -way pressure adjustment loop

6) The regulation circuit of multiple overflow valves

7) The decompression circuit of the pressure decompression valve

8) The load load load on the directional valve

9) The load -loading circuit of the pilot overflow valve

10) Balanced circuit of order valve

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap