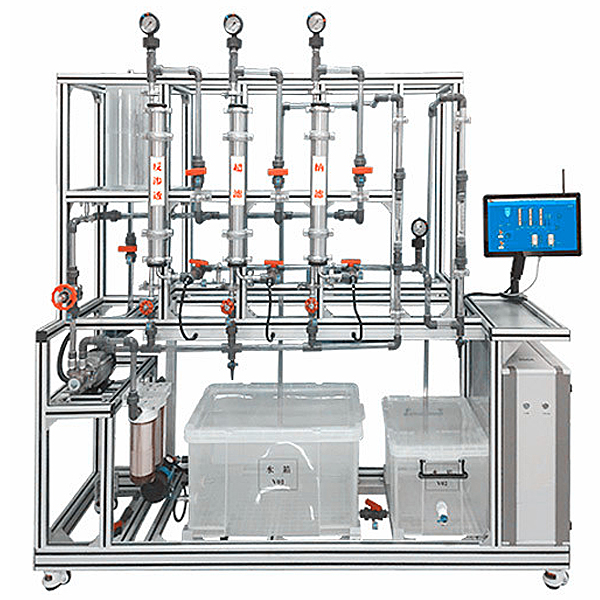

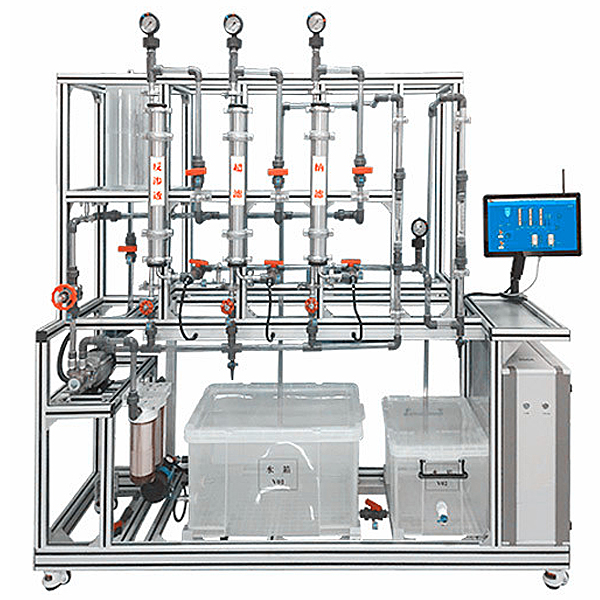

DYHGGY-20 Multifunctional Membrane Separation Training Platform

Release time:2024-06-15 11:30viewed:times

. Features:

1. The pressurized power component uses a st*nless steel multi-stage high-pressure centrifugal pump, which has the advantages of high pressure, high efficiency, corrosion resistance, strong self-priming ability, etc. The pressure and flow can be adjusted freely.

2. The overall structure is compact, the operation is simple, and the operating volume is small.

3. The system uses transparent plastic pipes and accessories, which are high pressure-bearing, corrosion-resistant, and have good sealing.

Device functions:

1. Reflect the basic structure and process of membrane separation components.

2. System experiments of four membrane separation processes, ultrafiltration, microfiltration, reverse osmosis nanofiltration, and nanofiltration, can be carried out; master the adaptability and operation methods of the four membranes.

3. The recovery rate and desalination rate can be calculated according to the flow rate and salt content of the influent, concentrated water and clean water; study the m*n factors affecting the separation performance of the reverse osmosis membrane and their influencing laws.

M*n configuration:

outlet tank, raw water tank, high-pressure pump, centrifugal pump, pre-filter, reverse osmosis membrane assembly, nanofiltration membrane assembly, ultrafiltration assembly, microfiltration membrane assembly, pressure gauge, liquid flow meter, pressure controller, conductivity meter, pipeline, valve, high-quality aluminum alloy profile frame.

Utilities:

Water: The device comes with a water tank, connected to tap water. During the experiment, the water is pumped into the system by the water tank circulation pump and circulated.

Electricity: Voltage AC380V, power 2.0KW, standard three-phase four-wire system. Each laboratory needs to be equipped with 1 to 2 grounding points (safety ground and signal ground).

Experimental materials: tap water or polyethylene glycol, external equipment: spectrophotometer

Technical parameters:

1. Pre-filter: 20-inch 5μm coarse filter, quantity 2.

2. The reverse osmosis membrane assembly adopts 4040 type membrane, membrane diameter: φ100mm; length: 1014mm; desalination rate: 95%; maximum pressure: 3.16MPa. St*nless steel pressure vessel is used.

3. Ultrafiltration membrane assembly: polypropylene mesoporous fiber, pore size: 0.01-0.3μm, porosity: 50%-55%, molecular weight cutoff: 50,000, operating temperature: 44℃-73℃; maximum working pressure: 4Kg/cm2, water output is 60-600L/h.

4. Nanofiltration membrane assembly uses 4040 type membrane, st*nless steel shell, inlet pH value 3.0-10, maximum inlet temperature 45-80℃. St*nless steel pressure vessel is used.

5. Microfiltration membrane assembly: block carbon + engineering plastic shell, water output 250-2500L/H, pore size 0.2μm.

6. Conductivity meter measurement: reverse osmosis membrane inlet water, outlet fresh water, outlet concentrated water, nanofiltration membrane inlet water, outlet fresh water, outlet concentrated water concentration changes. A total of 6 online conductivity meters, range 0-1999μS/cm.

7. Microfiltration membrane outlet flow rate: tubular flowmeter, measuring range 60-600L/h.

8. Ultrafiltration membrane fresh water and concentrated water flow rate: tubular flowmeter, measuring range 25-250L/h.

9. Reverse osmosis membrane fresh water and concentrated water flow rate: tubular flowmeter, measuring range 16-160L/h.

10. Nanofiltration membrane fresh water and concentrated water flow rate: tubular flowmeter, measuring range 16-160L/h.

11. Pressure: st*nless steel pointer shockproof pressure gauge, measuring range 0-0.6MPa and 0-1.6MPa.

12. St*nless steel multi-stage high-pressure centrifugal pump: flow range 1.0-2.5 m3/h, head 40-102m, power 0.75KW. 13. St*nless steel

centrifugal pump: flow range 0.5-3.5 m3/h, head 16-28m, power 0.55KW.

14. Original water tank: volume 80L, high-quality PP material, thickness 8mm.

15. Water outlet tank: volume 80L, high-quality PP material, thickness 8mm.

16. Pipeline: transparent, wall thickness ≥2.0mm, transparent visible material.

17. Pressure switch: 0~0.6MPa, low pressure protection, delayed protection.

18. Voltage: 380V, total power: 2.0kW.

19. Chint Electric: contactor, light switch, leakage protection *r switch.

20. Dimensions: 2000×550×2000mm (length×width×height), movable design, with brake wheel, high-quality aluminum alloy profile frame, no welding point, easy installation and disassembly, horizontal adjustment support casters.

21. Engineering identification: including equipment position number, pipeline flow arrow and identification, valve position number and other engineering equipment concept matching, so that students are in a safe experimental operation environment, learn to recognize engineering pipeline identification, and cultivate students' engineering concept.

22. Virtual simulation software for electrical installation of building and intelligent building Designed based on unity3d, users can choose different sizes of interactive interface according to computer configuration, and can choose six levels of image quality. The model in the software can be rotated 360°, enlarged, reduced, and translated. There are assistant prompts during the use of the software, as follows: A. Wet alarm system 1. System overview: Overview of wet alarm system 2. Equipment recognition: It has the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (built-in 6 multiple-choice questions, with prompts for correct and wrong choices), schematic diagram (you can enter the equipment from the schematic diagram). The equipment includes: sprinkler, water flow indicator, signal butterfly valve, exhaust valve, fire alarm control, high pressure gauge, high-level water tank, Wia control cabinet, pressure regulating tank, flow switch, end water test device, dr*nage facilities, water pump connector, hydraulic alarm, delay, wet alarm, butterfly valve, check valve, fire pump, safety pressure regulating valve, fire water tank.

3. Principle display: Display the working principle of the wet alarm system, 3D animation demonstration, 3D model is semi-transparent, and the internal water flow can be seen. Equipped with exercise module (4 multiple-choice questions are built-in, and there are prompts for correct and wrong choices)

4. Design layout: There are multiple-choice questions and calculation questions, each of which is scored, and the correct answer and score are displayed after submission

B. Gas fire extinguishing system

1. System overview: Overview of gas fire extinguishing system

2. Equipment recognition: There are optimal viewing angles, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (8 built-in multiple-choice questions, and there are prompts for correct and wrong choices), and schematic diagrams (you can enter the equipment from the schematic diagram). The equipment includes: nozzles, HFC-227 storage bottles, bottle head valves, heptafluoropropane check valves, high-pressure hoses, gas check valves, safety valves, weighing alarms, electromagnetic starters, selection valves, smoke alarms, and fire alarm controllers.

3. Principle display: Display the working principle of the gas fire extinguishing system, 3D animation demonstrations, and 3D models are semi-transparent, and the internal gas can be seen. Equipped with practice module (built-in 3 multiple-choice questions, with prompts for correct and wrong choices)

4. Design and layout: There are 6 multiple-choice questions, each with scores, and the correct answer and score will be displayed after submission

. C. Escape drill: Teaching in the form of fun games, escape from the burning room within a limited time, and wrong choices will directly enter the score interface.

Wechat scan code follow us

Wechat scan code follow us