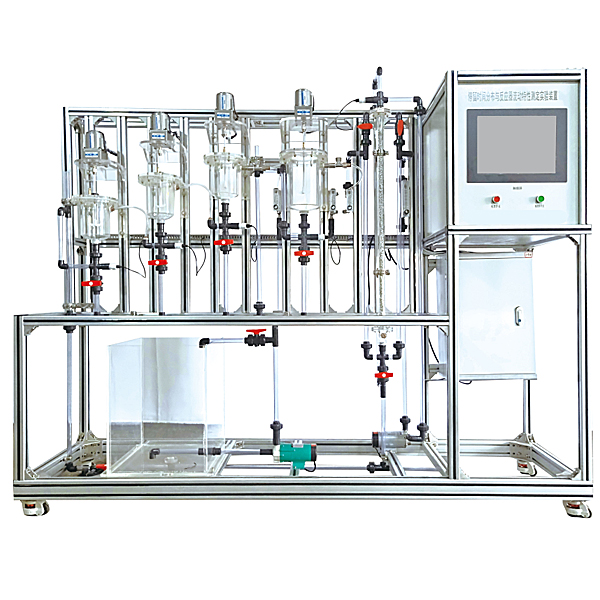

DYHGGY-11 Residence Time Distribution and Reactor Flow Characteristics Determination Training Platform

Release time:2024-06-15 07:00viewed:times

Device function:

1. Compare and study the residence time distribution and flow characteristics of kettle and tubular reactors.

2. Analyze and study the residence time distribution and backmixing degree of kettle and tubular reactors through the parameters of the multi-kettle series model . The model parameter N represents the backmixing degree of the reactor. The larger the N, the smaller the backmixing degree, and then guide students to understand the two ideal modes of plug flow and full mixing flow.

3. The device can be operated with no circulation and variable circulation ratio R respectively, and the residence time distribution of tubular reactors can be determined under different backmixing degrees.

4. The device uses the pulse tracer method to determine the residence time distribution. The conductivity meter can accurately detect and record the concentration of the tracer at the outlet of each reactor in real time, and obt*n various parameters through software processing.

5. Full touch integrated control, high-stability data transmission, hardware encryption.

Design parameters:

normal temperature and normal pressure operation.

Single kettle:

water flow rate: 40L/h, average residence time (mathematical expectation value) t: 200-600.

Variance δt2: 1.0×105--3.0×105, model parameter N: 1.2-2.

Three kettles:

water flow rate: 40L/h, average residence time (mathematical expectation) t: 200-600.

Variance δt2: 1.0×105--5.0×105, model parameter N: 1.2-4.

M*n configuration:

organic glass reactor, tubular reactor, rotor flowmeter, water tank, water pump, motor , digital conductivity meter valve, pipeline, central processor, touch screen, high-quality aluminum alloy profile frame.

Utility water: The device comes with a transparent water tank, connected to the tap water.

Electricity: voltage AC220V, power 1.0KW, standard single-phase three-wire system. Each laboratory needs to be equipped with 1~2 grounding points (safety ground and signal ground).

Experimental materials: water-KCl.

M*n equipment:

1. Kettle reactor 1.0L, made of transparent organic glass, quantity 3.

2. Kettle reactor 3.0L, made of transparent organic glass, quantity 1.

3. Tubular reactor: diameter Φ35, length 1200mm, packing Raschig ring φ4mm.

4. Water tank: 80L, transparent organic glass material.

5. Pipeline: transparent, wall thickness ≥2.0mm, transparent visible material.

6. AC adjustable speed motor: power 15W, stepless speed regulation.

7. Water inlet pump: MP type magnetic drive pump, rated power: 15W, rated flow: 6L/min.

8. Circulation pump: rated flow 6L/min, head 3m.

9. Digital conductivity meter: 0~2000μS/cm, photoelectric coupler isolation protection 4-20ma signal output, conductivity electrode: 5. 485 communication interface conversion, standard MODBUS RTU communication protocol, automatic data processing and screen display of experimental curves and data, automatic temperature compensation: 0-100℃.

10. Rotor flowmeter: flow 6-60L/h, water.

11. Central processing unit: execution speed 0.64μs, memory capacity 16K, built-in Ethernet supports Modbus TCP and Ethernet/IP communication protocols; function: data processing operation.

12. Analog module: up to 16-bit resolution, total accuracy ±0.5%, built-in RS485 communication mode.

13. Adopt all-in-one tablet touch computer, full digital touch screen control operation. HMI: projection touch technology, 50 million touch points, memory 4G, function: central processor data display control.

14. Rated voltage: 220V, total power: 1kW.

15. Dimensions: 2000×550×2000mm (length×width×height) The appearance is a movable design, with brake wheels, high-quality aluminum alloy profile frame, no welding points, easy installation and disassembly, horizontal adjustment support casters.

16. A set of conversion modules and online monitoring software.

17. Engineering identification: including equipment position number, pipeline flow arrow and identification, valve position number and other engineering equipment concept matching, so that students are in a safe experimental operation environment, learn to recognize engineering pipeline identification, and cultivate students' engineering concepts.

18. Virtual simulation software for electrical installation of building and intelligent building Designed based on unity3d, users can choose different sizes of interactive interface according to computer configuration, and can choose six levels of image quality. The model in the software can be rotated 360°, enlarged, reduced, and translated. There are assistant prompts during the use of the software, as follows: A. Wet alarm system 1. System overview: Overview of wet alarm system 2. Equipment recognition: It has the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (built-in 6 multiple-choice questions, with prompts for correct and wrong choices), and schematics (you can enter the equipment from the schematics). The equipment includes: sprinklers, water flow indicators, signal butterfly valves, exhaust valves, fire alarm controls, high pressure gauges, high-level water tanks, Wia control cabinets, pressure regulators, flow switches, end water test devices, dr*nage facilities, water pump connectors, hydraulic alarms, delays, wet alarms, butterfly valves, check valves, fire pumps, safety pressure regulators, and fire water tanks. 3. Principle demonstration: Demonstrate the working principle of the wet alarm system, 3D animation demonstration, 3D model is semi-transparent, and the internal water flow can be seen. Equipped with practice module (built-in 4 multiple-choice questions, with prompts for correct and wrong choices) 4. Design layout: There are multiple-choice questions and calculation questions, each of which is scored, and the correct answer and score will be displayed after submission

B. Gas fire extinguishing system

1. System overview: Overview of gas fire extinguishing system

2. Equipment recognition: It is equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (8 built-in multiple-choice questions, with prompts for correct and wrong choices), and schematic diagrams (you can enter the equipment from the schematic diagram). The equipment includes: nozzles, HFC-227 storage bottles, bottle head valves, heptafluoropropane one-way valves, high-pressure hoses, gas one-way valves, safety valves, weighing alarms, electromagnetic starters, selection valves, smoke alarms, and fire alarm controllers.

3. Principle display: Display the working principle of the gas fire extinguishing system, 3D animation demonstration, and the 3D model is semi-transparent, so that the internal gas can be seen. Equipped with an exercise module (3 built-in multiple-choice questions, with prompts for correct and wrong choices)

4. Design layout: There are 6 multiple-choice questions, each of which is scored, and the correct answer and score will be displayed after submission.

C. Escape drills: Teaching is carried out in the form of fun games. Escape from the burning room within a limited time. If you make a wrong choice, you will directly enter the score interface.

Wechat scan code follow us

Wechat scan code follow us