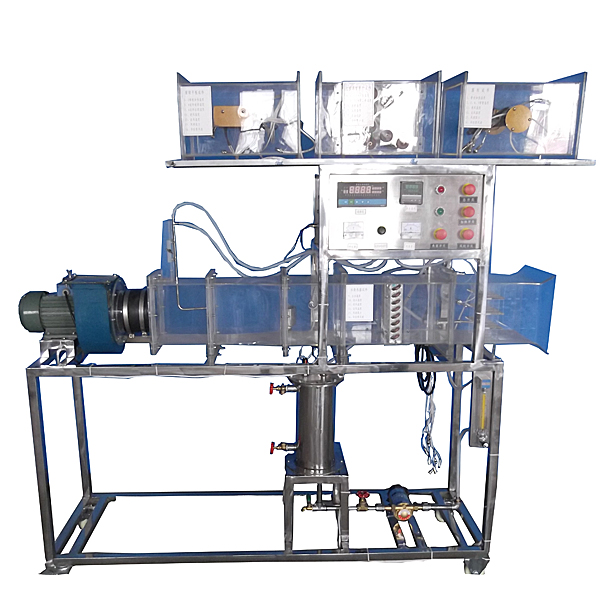

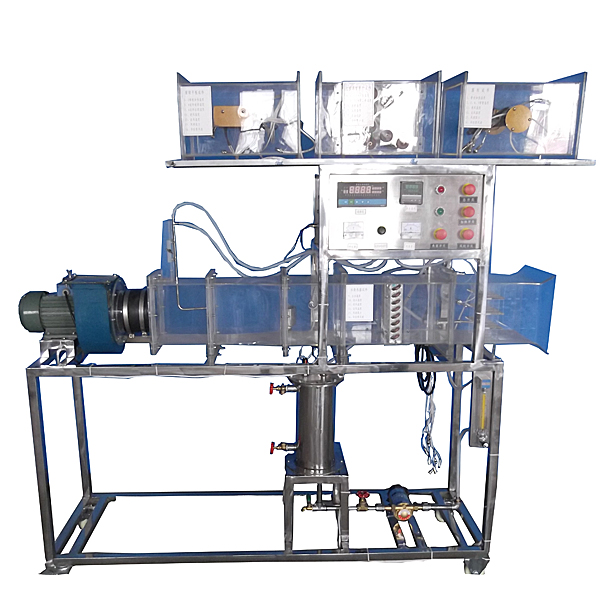

dyHGRG-32 forced convection comprehensive test and training device

Release time:2024-06-12 05:30viewed:times

Technical parameters:

1. Input power supply: single-phase AC220V±10% 50Hz, power 5.0KW.

2. The experimental *r duct is made of transparent organic glass and is divided into an *r outlet section, an experimental section (the experimental section can be disassembled and replaced), a test section, etc., which are connected by flange nuts.

3. Centrifugal fan parameters: *r volume 1000 m3/h, wind pressure 1000 Pa, power 370W.

4. Rotating cylindrical specimen, experimental tube specification: Φ32 × 250mm, made of copper tube. An electric heater with a power of 300W is installed in the tube as a heat source, and four thermocouples are embedded in the tube wall to measure the wall temperature.

5. Copper flat plate specimen, specifications: δ=4 mm, length 250mm, width 150mm, flat electric heater power: ≤500W.

6. The gas-water heat exchanger test piece uses water to heat the gas. The hot water flows through the small heat exchanger to cool down, and the *r heats up through the small heat exchanger. Hot water is heated by an electric heater. The heat exchanger area is 1.0m2, the water flow rate is 16~160L/h, and the liquid heating power is 2.0KW.

7. Tube tube external heat release test piece: fin type (aluminum rolled tube) heat pipe heat exchanger, size Φ20 × 250mm, material red copper tube. Arrange in a cross row or in a row.

8. Pitot tube flowmeter is equipped with a differential pressure sensor : range 0-1000Pa, accuracy 0.5.

9. Temperature measurement: The measurement system is equipped with an intelligent temperature control instrument (PID temperature control, accuracy ±0.2°C) and a high-precision PID voltage regulation module circuit.

10. The universal signal input inspection instrument is combined with a high-precision digital display meter to display all experimental measurement parameters such as temperature, resistance, flow rate, etc., and the manual damper adjusts the *r volume.

11. Dimensions: 2000×500×1700mm. The shape is a st*nless steel movable bracket with double brake wheels.

12. Virtual simulation software for electrical installation of building buildings and smart buildings. Based on unity3d design, users can choose different interactive interface sizes according to computer configuration, and can choose from six image quality levels. The model in the software can be rotated 360°, enlarged, reduced, and translated. There are assistant prompts during the use of the software, and the content is as follows: A. Wet alarm system 1. System overview: Overview of wet alarm system 2. Equipment awareness: equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), and exercises (Built-in 6 multiple-choice questions, prompts for correct and incorrect choices), schematic diagram (can be entered into the device from the schematic diagram). Equipment includes: nozzle, water flow indicator, signal butterfly valve, exhaust valve, fire alarm control, high pipe pressure gauge, high water tank, Wia control cabinet, pressure stabilizing tank, flow switch, terminal water testing device, dr*nage facilities, water pump connection alarms, hydraulic alarms, delayers, wet alarms, butterfly valves, check valves, fire pumps, safety pressure regulators, and fire pools. 3. Principle display: Show the working principle of the wet alarm system, three-dimensional animation demonstration, the three-dimensional model is translucent, and the internal water flow can be seen. Equipped with a practice module (built-in 4 multiple-choice questions, with prompts for correct and incorrect choices) 4. Design layout: There are multiple-choice questions and calculation questions, each question is scored, and the correct answer and score will be displayed after submission B. Gas fire extinguishing system 1. System overview: Overview of gas fire extinguishing system 2. Equipment awareness: equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (built-in 8 multiple-choice questions, with prompts for correct and incorrect choices), Schematic diagram (access to the device from the schematic diagram). Equipment includes: nozzle, HFC-227 storage bottle, bottle head valve, heptafluoropropane one-way valve, high-pressure hose, gas one-way valve, safety valve, weighing alarm, electromagnetic starter, selection valve, smoke alarm, fire Alarm controller. 3. Principle display: Show the working principle of the gas fire extinguishing system, three-dimensional animation demonstration, the three-dimensional model is translucent, and the internal gas can be seen. Equipped with a practice module (built-in 3 multiple-choice questions, with prompts for both correct and incorrect choices) 4. Design and layout: There are 6 multiple-choice questions, each question is scored, and the correct answer and score will be displayed after submission. C. Escape drill: adopted Teaching is conducted in the form of fun games. Escape from the burning room within a limited time. If you make a wrong choice, you will directly enter the score interface. Experimental purposes: 1. Forced convection single tube external heat release coefficient test. 2. Forced convection tube external heat release coefficient test. 3. Test of heat release coefficient of forced convection *r across flat plate and across rotating cylinder. 4. Test the heat transfer coefficient of forced convection *r through the water heat exchanger. M*n configuration: centrifugal fan, automatic *r damper, combined plexiglass wind tunnel, plexiglass experimental tube section, plexiglass fork row and parallel row experimental section, rotating cylinder test piece, copper flat test piece, regulated power supply potentiometer Adjust heating power, ammeter, voltmeter, Pitot tube and differential pressure sensor, thermal resistance temperature measurement, inspection instrument to display temperature, resistance, flow, st*nless steel bench, etc.

Wechat scan code follow us

Wechat scan code follow us