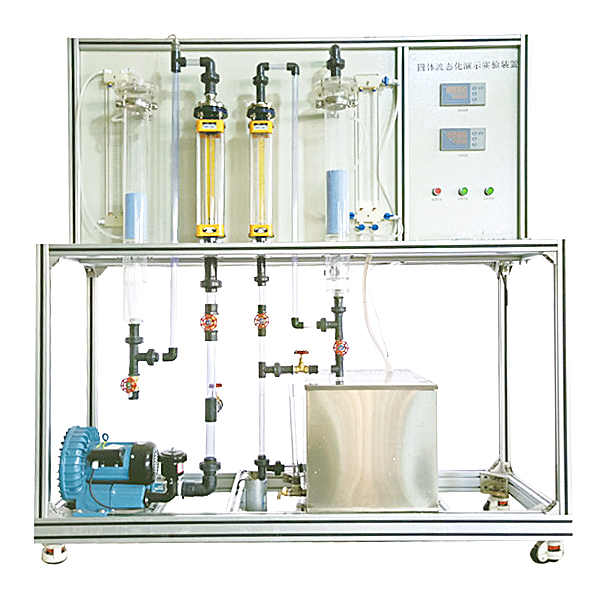

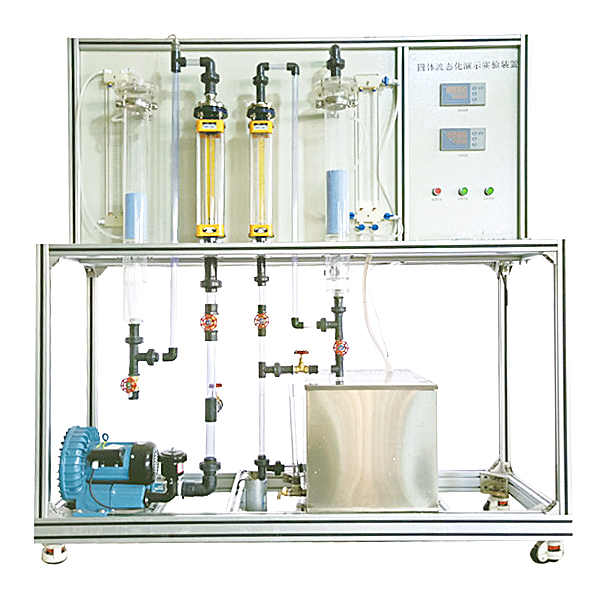

DYHGYL-02 solid duty training platform

Release time:2024-06-08 05:30viewed:times

Features of the device

1. The entire device is beautiful and elegant, with reasonable structural design, strong sense of integrity, and a strong sense of engineering, which can fully embody the concept of a modern laboratory .

2. The entire equipment is a self-propelled frame structure and is equipped with restr*ning feet to facilitate the disassembly, m*ntenance and transportation of the system.

3. The bed part of this experimental device is made of fully transparent high-quality organic glass. The experimental phenomena are clear and convenient for students to observe.

4. This experimental device shows the phenomenon of convergence and dispersion fluidization intuitively and stably, and has good experimental results.

5. The device design allows for 360-degree observation, enabling all-round teaching and experimentation.

Device functions

1. Observe the experimental phenomena of convergent and dispersed fluidization and the differences between them.

2. Master the measurement method of fluid flow characteristics through particle bed.

3. Determine the bulk density and void ratio of the bed.

4. Measure the fluidization curve and critical fluidization velocity of the *r bed and water bed respectively.

Design parameters:

Normal pressure and normal temperature operation.

The flow velocity in the fluidized bed is 0.2m/s, and the pressure drop in the fluidized bed is 0.06-0.6KPa.

Liquid flow: 40-400L/h.

Gas flow: 2.5-25 m3/h.

Utility water: The device comes with a transparent water tank and is connected to tap water. During the experiment, it enters the fluidized bed through a water pump and is recycled.

Electricity: voltage AC220V, power 1KW, standard single-phase three-wire system. Each laboratory needs to be equipped with 1~2 grounding points (safety ground and signal ground).

Air: Air comes from a low-noise fan (self-cont*ned *r source).

Experimental materials: quartz sand, external equipment: none

M*n equipment

1. Blower: vortex *r pump, power 550W, maximum flow 70m3/h.

2. The water pump is a 304 st*nless steel booster pump with a rated flow of 15L/min, a power of 90W, and a head of 12m.

3. Fluidized bed tube inner diameter: φ70mm; height: 700mm, made of high-quality fully transparent organic glass; the fixed bed height can reach 150mm, the fluidizing range can reach 550mm, and the bed body is marked with scales.

4. Fluid distributor and particle support plate, 40 mesh st*nless steel.

5. The bed particle filling is glass beads with a particle size of 0.8mm and a sphericity of 0.9.

6. Flow measurement: Use rotor flowmeter to measure, liquid flow: 40-400 L/h, gas flow: 2.5-25 m3/h.

7. Pressure difference measurement: The gas bed pressure difference measurement uses an inverted U-shaped pressure difference meter, and the liquid bed pressure difference measurement uses a U-shaped pressure difference meter.

8. Temperature measurement and control system: including temperature sensors , temperature instruments, etc. Temperature control sensor: Pt100 type platinum thermal resistance temperature measurement, st*nless steel probe, digital display, accuracy level ±0.1%; Temperature meter: The input adopts a digital correction system, with built-in nonlinear correction tables for commonly used thermocouples and thermal resistors, making the measurement accurate and stable. The product has been tested by a third-party authoritative organization and obt*ned the CE certification mark.

9. Water tank: 90L volume, high-quality transparent organic glass, with water storage and emptying bottom valve, pipeline return water and pump suction inlet partition plate design.

10. Air buffer tank: Made of 304 st*nless steel, the *r is buffered and stabilized before being fed into the bed.

11. Pipeline: transparent material, wall thickness ≥2.5mm.

12. Contactors, switches, leakage protection *r switches.

13. Instrument cabinet: Measurement and control and electrical equipment are on the experimental rack.

14. Dimensions: 1650×550×1800mm (length×width×height), movable design, with brake wheels, high-quality aluminum alloy profile frame, no welding points, easy installation and disassembly, horizontally adjustable support casters.

15. Engineering markings: including equipment tags, pipeline flow direction arrows and logos, valve tags and other engineering equipment concepts, so that students can be in a safe experimental operating environment, learn to recognize engineering pipeline markings, and cultivate students' engineering skills concept.

16. Virtual simulation software for electrical installation of building buildings and smart buildings. Based on unity3d design, users can choose different interactive interface sizes according to computer configuration, and six levels of image quality are av*lable. The model in the software can be rotated 360°, enlarged, reduced, and translated. There are assistant prompts during the use of the software, and the content is as follows: A. Wet alarm system 1. System overview: Overview of wet alarm system 2. Equipment awareness: equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), and exercises (Built-in 6 multiple-choice questions, prompts for correct and incorrect choices), schematic diagram (can be entered into the device from the schematic diagram). Equipment includes: nozzle, water flow indicator, signal butterfly valve, exhaust valve, fire alarm control, high pipe pressure gauge, high water tank, Wia control cabinet, pressure stabilizing tank, flow switch, terminal water testing device, dr*nage facilities, water pump connection alarms, hydraulic alarms, delayers, wet alarms, butterfly valves, check valves, fire pumps, safety pressure regulators, and fire pools. 3. Principle display: Show the working principle of the wet alarm system, three-dimensional animation demonstration, the three-dimensional model is translucent, and the internal water flow can be seen. Equipped with a practice module (built-in 4 multiple-choice questions, with prompts for correct and incorrect choices) 4. Design layout: There are multiple-choice questions and calculation questions, each question is scored, and the correct answer and score will be displayed after submission B. Gas fire extinguishing system 1. System overview: Overview of gas fire extinguishing system

2. Equipment awareness: equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (built-in 8 multiple-choice questions, prompts for correct and incorrect choices), schematic diagram (can be entered from the schematic diagram) into the device). Equipment includes: nozzle, HFC-227 storage bottle, bottle head valve, heptafluoropropane one-way valve, high-pressure hose, gas one-way valve, safety valve, weighing alarm, electromagnetic starter, selection valve, smoke alarm, fire Alarm controller.

3. Principle display: Demonstrate the working principle of the gas fire extinguishing system, three-dimensional animation demonstration, the three-dimensional model is translucent, and the internal gas can be seen. Equipped with a practice module (built-in 3 multiple-choice questions, with prompts for both correct and incorrect choices)

4. Design layout: There are 6 multiple-choice questions, each question is scored, and the correct answer and score will be displayed after submission.

C. Escape drill: adopted Teaching is conducted in the form of fun games. Escape from the burning room within a limited time. If you make a wrong choice, you will directly enter the score interface.

Wechat scan code follow us

Wechat scan code follow us