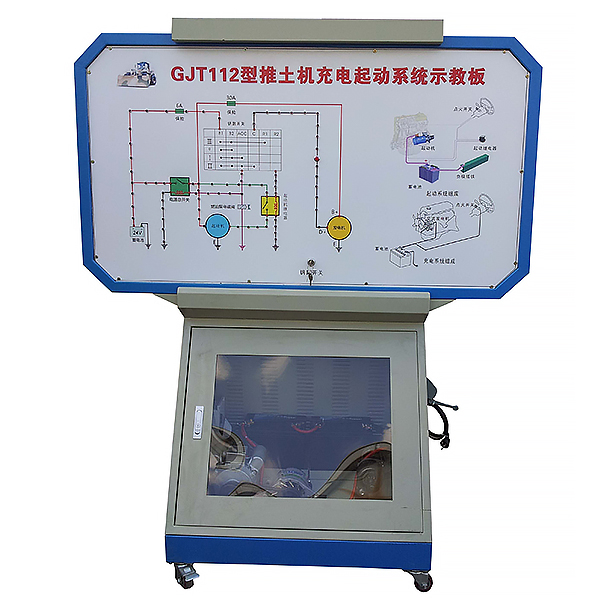

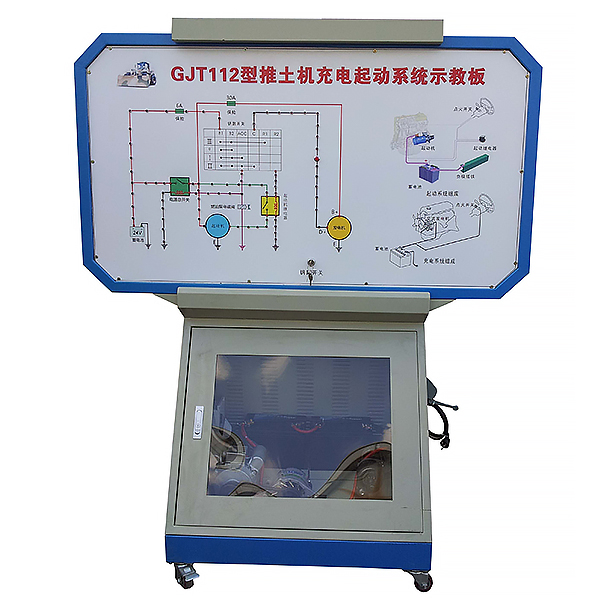

| serial number | Name | Specifications and models | unit | quantity |

| 1 | Test control panel |

Equipped with various detection terminals, color circuit diagram and working principle diagram (panel: 1200*900*4mm) |

set | 1 |

| 2 | Ignition Switch | brand new | indivual | 1 |

| 3 | Starter assembly | brand new | Only | 1 |

| 3 | dynamo | brand new | Only | 1 |

| 4 | Starter assembly disassembled parts | set | 1 | |

| 5 | Generator assembly disassembled parts | set | 1 | |

| 6 | starter relay | indivual | 1 | |

| 7 | Voltmeter | 0~30V | indivual | 1 |

| 8 | Ammeter | 0~500A | indivual | 1 |

| 9 | battery | 46B24SR, 12V 45Ah, 550CCA | tower | 2 |

| 10 | m*n power switch | 50A | indivual | 1 |

| 11 | R-shaped mobile stand (with self-locking casters) | 1600×700×1700mm (length×width×height) | tower | 1 |

| 12 | Fault simulation and troubleshooting device | set | 1 | |

| 13 | charging indicator | indivual | 1 | |

| 14 | Three-phase asynchronous motor | YT100L1-4 | tower | 1 |

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap