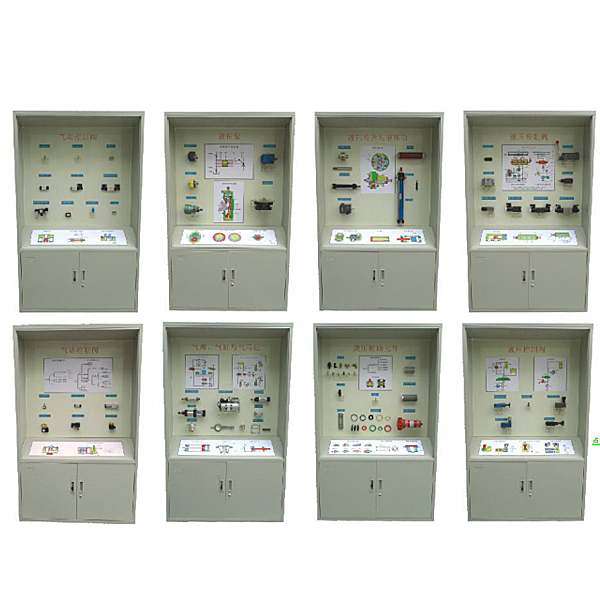

| serial number | name | Checklist | Checklist |

| 1 | Hydraulic pump | gear pump | Working principle of hydraulic pump |

| External gear pump | |||

| Internal gear pump | |||

| vane pump | Single acting vane pump | ||

| plunger pump | Radial piston pump | ||

| Servo variable mechanism | |||

| Axial piston pump | |||

| 2 | Hydraulic motors and hydraulic cylinders | hydraulic motor | Vane hydraulic motor |

| Radial piston motor | |||

| Hydraulic cylinder type | plunger cylinder | ||

| Swing cylinder | |||

| Hydraulic cylinder structure | Piston and piston rod | ||

| buffer device | |||

| Single rod hydraulic cylinder | |||

| 3 | Hydraulic control valve | Directional control valve | Ordinary one-way valve |

| Two-position three-way solenoid valve | |||

| Hydraulic control check valve | |||

| Three-position five-way solenoid valve | |||

| Manual reversing valve | |||

| Two-position four-way solenoid valve | |||

| Motorized reversing valve | |||

| Three-position four-way solenoid valve | |||

| 4 | Hydraulic control valve | pressure control valve | Direct acting relief valve |

| Pilot operated relief valve | |||

| flow control valve | Fixed differential pressure reducing valve | ||

| Fixed ratio pressure reducing valve | |||

| 5 | Hydraulic transmission components | Pipe joint | Pipe joint |

| Quick Connector | |||

| filter | Surface coarse filter | ||

| paper filter | |||

| depth filter | |||

| Accumulator | Level gauge | ||

| silencer | |||

| 6 | Air source, cylinder and *r motor | Air compressor | small *r compressor |

| Compressor accessories | |||

| cylinder | Ordinary cylinder | ||

| Thin film cylinder | |||

| *r motor | Ordinary impact cylinder | ||

| Swing cylinder | |||

| vane motor | |||

| 7 | Pneumatic control valve | Directional control valve | One way control valve |

| Air pressure control directional valve | |||

| pressure control valve | Direct acting solenoid valve | ||

| Pilot solenoid valve | |||

| Direct acting solenoid valve | |||

| Delay reversing valve | |||

| 8 | Pneumatic control valve | flow control valve | Exhaust throttle valve |

| Flexible throttle valve | |||

| Proportional valves and servo valves | OR element | ||

| Double pneumatic control valve | |||

| Single solenoid valve | |||

| Three-position five-way solenoid valve | |||

| pneumatic logic components | Gas triple piece pressure reducing valve | ||

| Non-access control door components | |||

| is the gate and gate component | |||

| or non-element |

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap