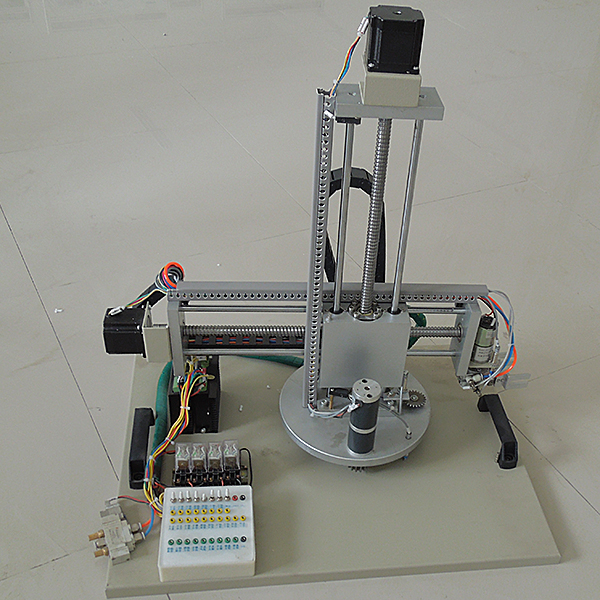

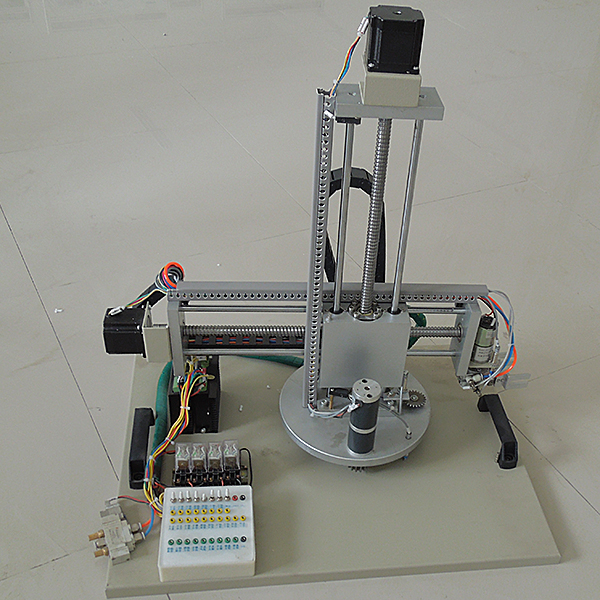

Overview

The four-degree-of-freedom manipulator tr*ning model is a miniature of the three-dimensional positioning system. It is controlled by a programmable controller and accurately drives the stepper motors in the three directions of the X, Y, and Z axes to transport and move items. It is a finished product with perfect execution. The organization can realize all action processes in modern logistics systems. Matching Mitsubishi FX1N-40MT.

The tr*ning device consists of an aluminum alloy guide r*l tr*ning platform , a manipulator device, a control system, etc. The tr*ning device is a coordinate manipulator, which can accurately control the position of the manipulator's rotation, arm vertical up and down, arm horizontal movement, and claw rotation with four degrees of freedom. At the same time, a transistor-type PLC programmable controller is configured for complex position control of the entire manipulator. The control part of the tr*ning device adopts standard module design and can be divided into power module, PLC module and system control module. It includes many technologies involved in the major, such as stepper motor drive, mechanical transmission, pneumatics , programmable controller, etc., providing students with a comprehensive tr*ning environment, so that the many single-subject professional knowledge that students have learned can be applied in Here you get comprehensive understanding, comprehensive tr*ning and mutual improvement.

Technical Parameters

Power supply: single-phase AC220V, 50Hz

Power: <200W

Size: not less than 600*400*500mm

Equipment structure:

The bench of the tr*ning device is of metal structure. The I/O terminals of the PLC module of the tr*ning and assessment device and the connecting terminals of common modules and PLC are all connected to safety sockets, and wires with safety plugs are used for circuit connection; each command switch, The circuits of photoelectric switches, sensors and indicating elements are connected through the terminal strip. The combination of plug-in and pull-out wire connection circuits and terminal connection circuits not only ensures the tr*ning, formation and consolidation of students' basic skills, but also ensures the speed, safety and reliability of circuit connections.

1. Manual/automatic control mode, for hardware detection and program verification.

2. The open actuator can be programmed according to different control schemes to form different execution systems, adapting to PLC learning and programming by personnel at different levels. It can also be used for project design or research.

3. The product is open and the overall mechanical structure is clearly visible.

4. Safety protection measures: The desktop of the tr*ning platform is made of high-density board with high insulation, high strength and high temperature resistance. It has grounding protection and leakage protection functions, and its safety complies with relevant national standards. Use high-insulation safety sockets and high-strength safety experimental wires with insulating sheaths.

5. The mechanical transmission of the horizontal and vertical axes of the manipulator uses high-precision ball screws, high-precision polished rod guides and linear bearings, coupled with advanced mechanical design , precision machining and assembly, to make the manipulator move very smoothly. Vertical and horizontal movement and horizontal rotation and precise position control.

6. Using selected stepper motors as the power source for the horizontal and vertical axes can achieve 0.028 degree subdivision, that is, 12,800 steps are required for each revolution, and the ball wire stroke is 4mm, so the arm's displacement accuracy per step is 0.0003125 mm, the normal single step angle of the stepper motor is 0.9, then the arm's displacement accuracy per step is 0.01mm.

7. The horizontal rotation of the robotic arm and gripper is driven by an advanced decelerated DC motor, which can achieve precise position control in the direction of rotation.

8. The mechanical gripper adopts a high-precision pneumatic gripper, equipped with an advanced electromagnetic position switch and a two-position three-way solenoid valve, which can achieve fast and accurate grabbing and releasing actions.

9. Using a transistor-type PLC programmable controller as the control host and configuring sensors, it can realize PLC advanced instruction programming and the technical application of photoelectric sensors.

10. The maximum horizontal rotation angle of the manipulator: 720 degrees.

11. The mechanical gripper adopts a high-precision pneumatic gripper, equipped with an advanced electromagnetic position switch and a two-position three-way solenoid valve, which can achieve fast and accurate grabbing and releasing actions.

Experiment content

1. Mechanical: mechanical installation and position adjustment of the device;

2. Electrical : wiring of electrical components, selection of execution motors;

3. Sensor: selection and application of micro photoelectric switches;

4. PLC: programming and application of PLC control driver.

5. Feeding mechanism control experiment

6. Cross manipulator inching control experiment

7. Cross manipulator three-dimensional precise positioning experiment

8. Cross manipulator picking up objects experiment

9. Cross manipulator placing objects experiment

10. Cross manipulator single cycle moving object experiment

M*n configuration (single unit):

|

Name |

model |

quantity |

unit |

|

|

PLC host |

Mitsubishi FX1N-40MT (optional) |

1 |

set |

|

|

Mitsubishi programming cable |

USB-SC09 |

1 |

strip |

|

|

stepper driver |

ST-26H |

2 |

set |

|

|

stepper motor |

F57 |

2 |

tower |

|

|

Lead screw |

1604 |

2 |

root |

|

|

polished rod |

Φ10 |

4 |

root |

|

|

Air claw |

MHZ2-16D |

1 |

indivual |

|

|

DC reduction motor |

Φ37/24v to |

2 |

indivual |

|

|

button |

Φ12 red, green |

2 |

indivual |

|

|

relay |

24V 20A |

4 |

indivual |

|

|

DC power supply |

24V 3A |

1 |

indivual |

|

|

software |

Demonstration board original program and Mitsubishi programming software |

Simulation teaching software |

1 |

set |

|

Industrial control configuration software |

||||

|

manual |

Experiment instructions |

1 |

book |

|

|

Connecting line |

red |

5 |

strip |

|

|

black |

5 |

strip |

||

|

green Line |

10 |

strip |

||

|

yellow line |

10 |

strip |

||

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap